-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Box Panel Roll Forming Machine

Box Panel Roll Forming Machine

1 Material thickness: 0.4-1.0mm PPGI,stainless steel

2 Mechanical property:the working speed is 4 plates/min

3 Coil size:feeding width range 900-1200mm

4 Punching hole range: Φ500-620mm

5 Length of the plate:According to customer requirement

Main configuration and the technology process of the machine

The whole line is including 10T hydraulic decoiler, laminator, lateral shear, leveling, coener cut, roll forming. Hydraulic mould cut the edgefold, output table, hydraulic station, and PLC system. Etc.

Hydraulic feeding →laminator→lateral shear→guide feeding →leveling →corner cut→roll forming →hydraulic cutting and edge fold→output

Roll forming machine:

The roll forming machine is including the machine frame, 7.5KW servo motor, precision screw rod, guide rail box type structure.

Main data :

a.Main machine structure: Box type structure

b.Drive mode:Chain wheel, gear drive

c.Main motor:5.5KW,380V, 50HZ(customized)

d.Main decelerator:5.5KW

e.Roller step:8 steps

f.Roll material:Cr12MoV

g.Main shaft:φ60mm

h.Cutting mode: Hydraulic cutting(7.5Kw)

i.Electronic mode:PLC control

j.Main roll forming machine working speed:About 10m/min

k.Machine dimension:6mx2.2mx1.4m

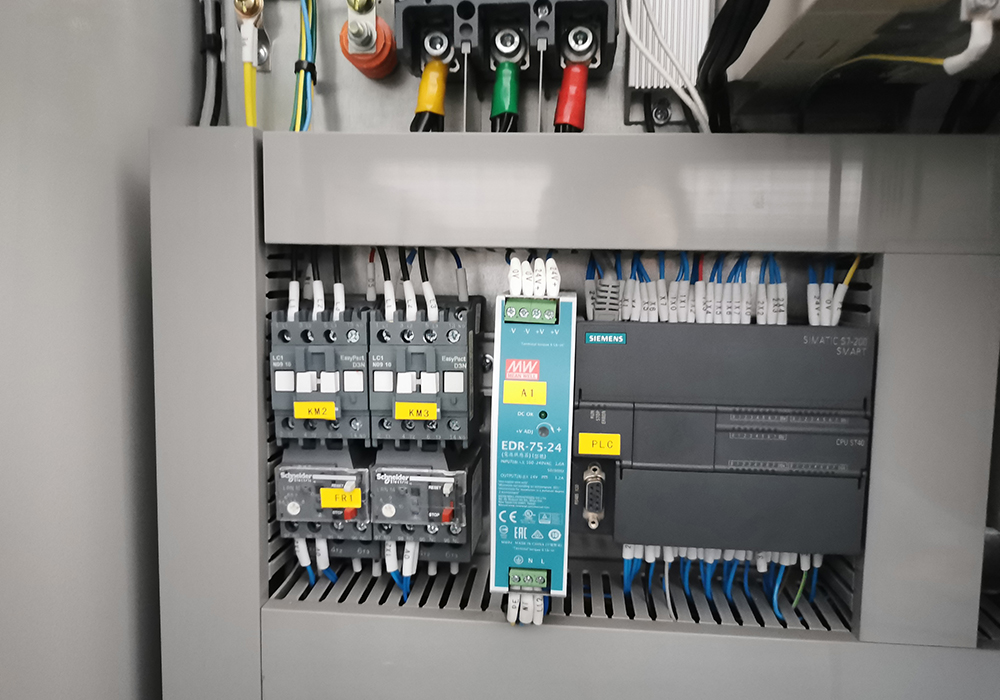

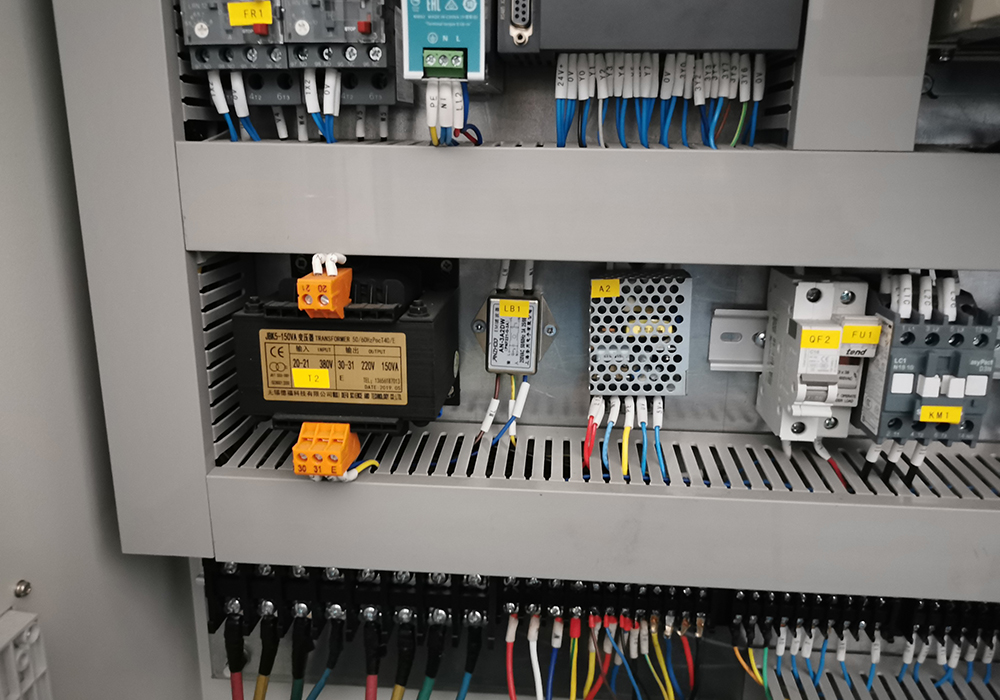

PLC system:

A.Under the manual or automatic mode to operate the switch and each components computor control.

B.Siemens PLC。Danvers frequency converter (Denmark)

C.7 inches touch screen

D.“set up”picture:set up the punching, cutting, length of the work piece,quantity of the end product, etc.

E.“Manual,Automatic”Picture:Selecting operation

F.“Monitoring”picture:Can observe the production situation.

G.Omron encoder to measure the length