-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

Ridge Cap roll forming machine can make different kind of ridge cap to meet the customer requirement. The ridge cap is applied to roofing sheet area. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min.There are many different shapes of ridge cap, we can make all kinds of machine if you can offer the profile to us.

Main data

|

No. |

Item |

Specification |

Unit |

|

1 |

Machine Type |

ridge cap |

|

|

2 |

Structure |

Wall board type |

|

|

3 |

Material |

PPGI |

|

|

4 |

Feeding width |

333 |

mm |

|

5 |

Effective width |

260 |

mm |

|

6 |

Thickness range |

0.3-0.6 |

mm |

|

7 |

Yield strength |

350 |

Mpa |

|

8 |

Forming speed |

12-18 |

m/min |

|

9 |

Roller steps |

14 |

Step |

|

10 |

Roller material |

45# forged steel, with hard chrome plating |

|

|

11 |

Main shaft material |

45# High quality steel, with quenching treatment |

|

|

12 |

Shaft diameter |

70 |

mm |

|

13 |

Main motor power |

5.5 |

KW |

|

14 |

Hydraulic station power |

5.5 |

KW |

|

15 |

Hydraulic station pressure |

12 |

Mpa |

|

16 |

Voltage |

According to the customer requirement |

|

|

17 |

Blade material |

Cr12 with quenching treatment |

|

|

18 |

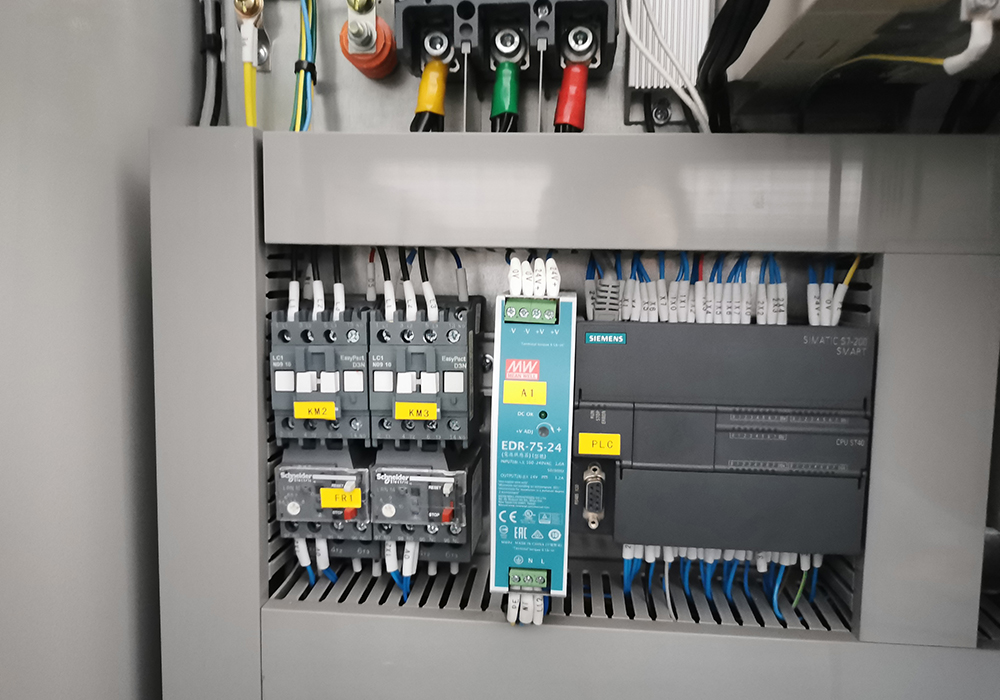

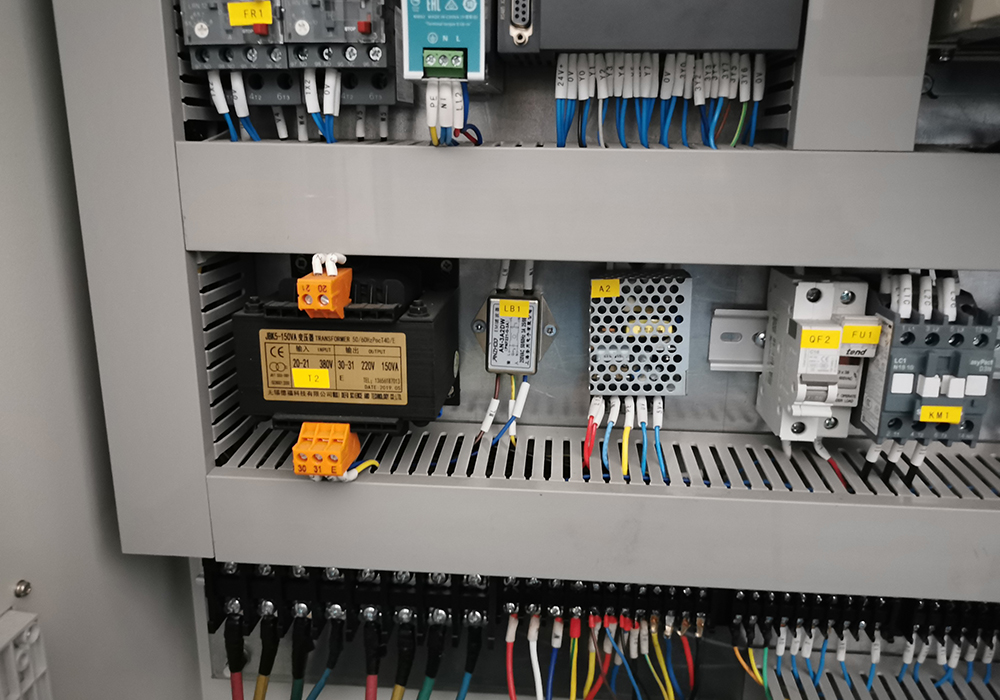

Electric system |

Panasonic PLC |

|

|

19 |

Cutting mode |

Hydraulic cutting, cutting after forming |

|

|

20 |

Machine color |

Blue +Yellow |

|

|

21 |

Container dimension |

1x20 |

GP |

Main features of the machine

The machine is including 3T manual feeder, drive device, roll forming machine, cutting machine, hydraulic system, electronic system, output table, etc.

Production Technology Process

Feeding → Leveling → forming → cutting after forming