-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Cable Cap Roll Forming Machine

Cable Cap Roll Forming Machine

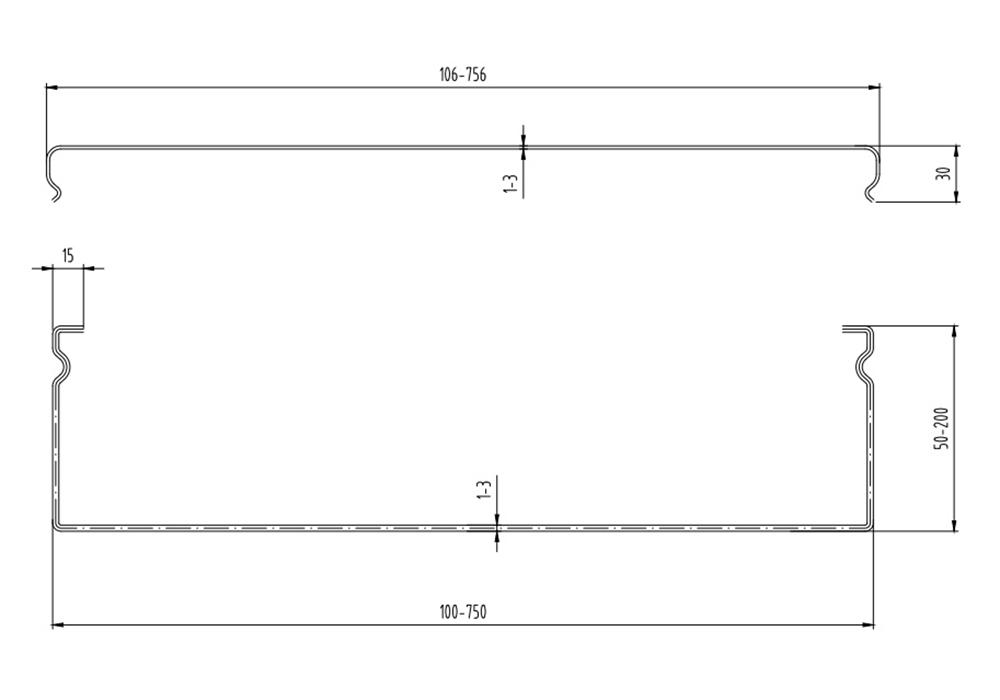

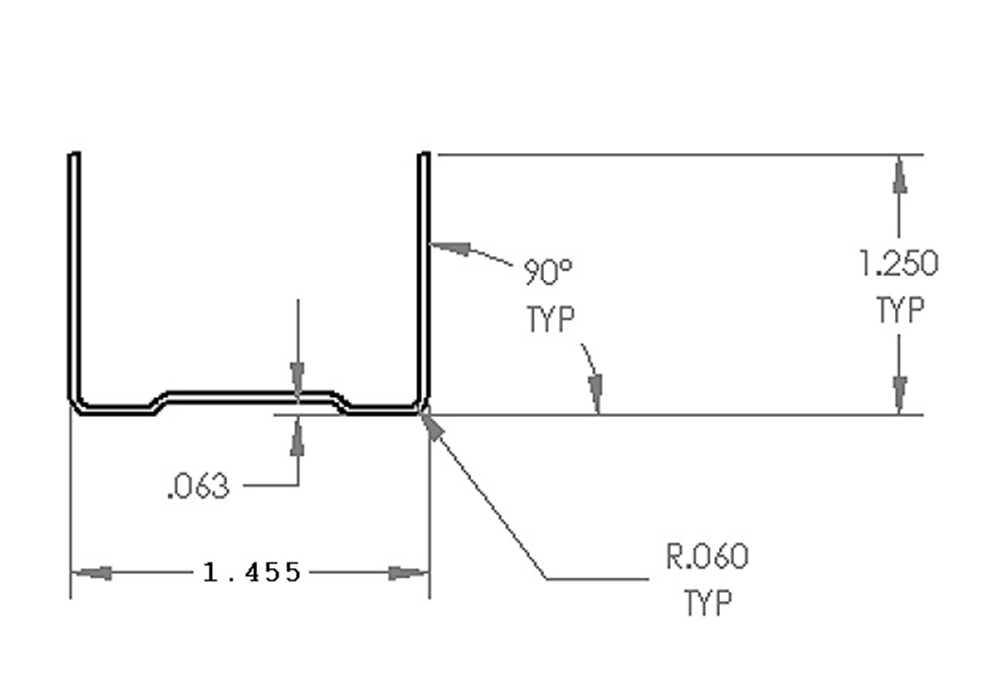

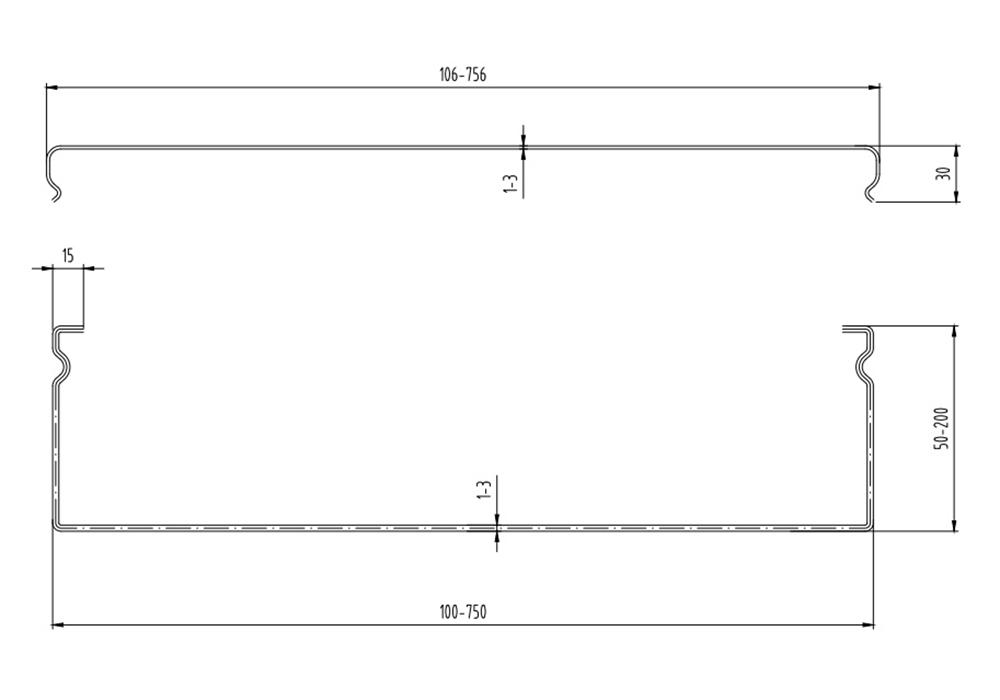

We are the professional manufacturer of making cable try roll forming system. The cable tray machine can make different sizes, the width and flange of the cable tray can be adjusted by automatic mode. The cutting mode can be post cutting or hydraulic cutting according to your requirement. We match the combined cutting to blade to cut all the sizes, when you change the profile, don’t need to change the cutting blade, just adjust the blade is ok. It is very easy to operate and run the machine, also can save your time and cost at the same time.

Most cable tray material is pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2.0mm.

Mean function of the cable tray and cap is support cable, protect cable and manage cable. If you want to learn more details of the cable tray machine, please contact us.

-

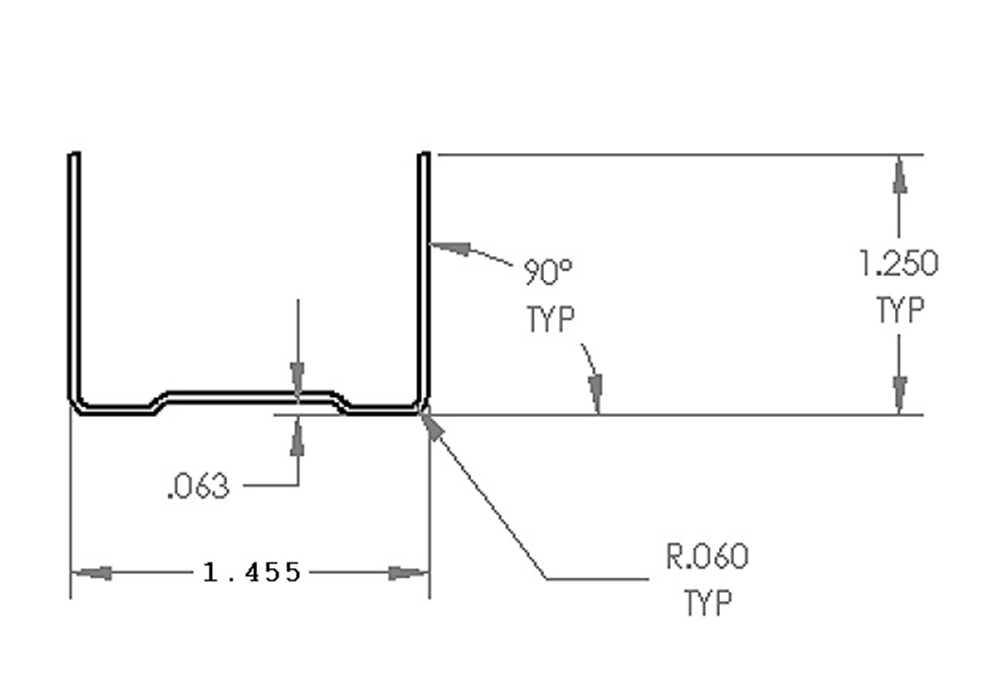

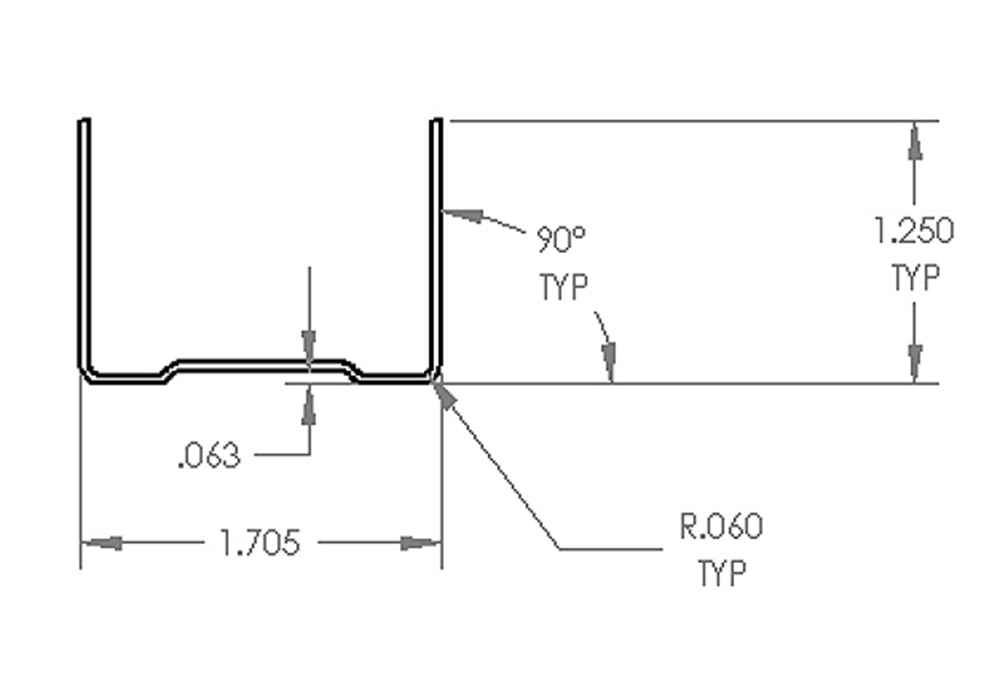

S34 x0.50

-

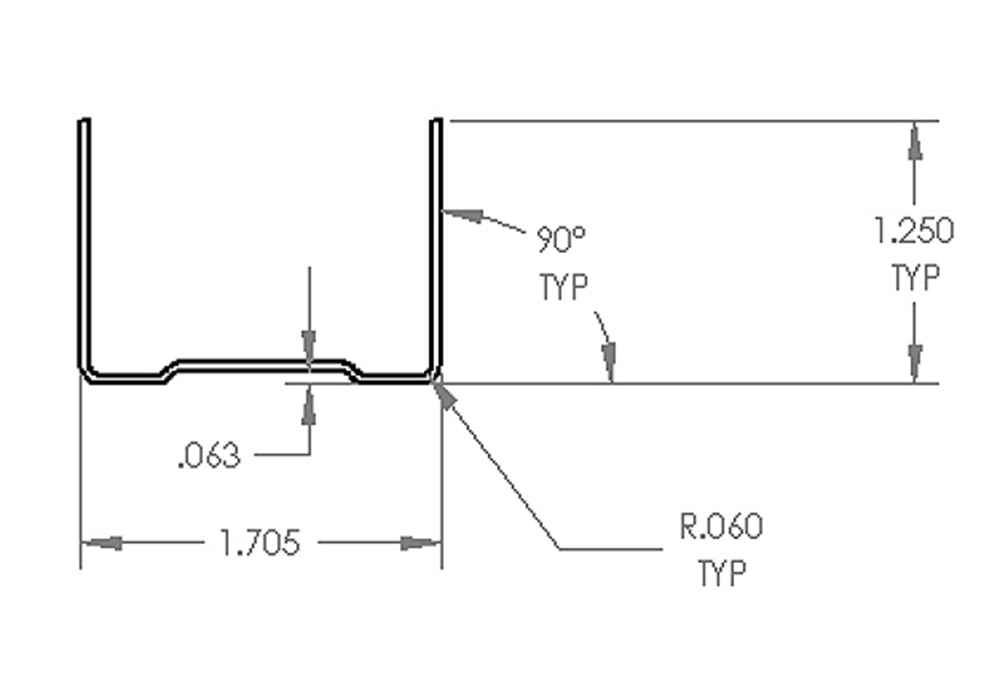

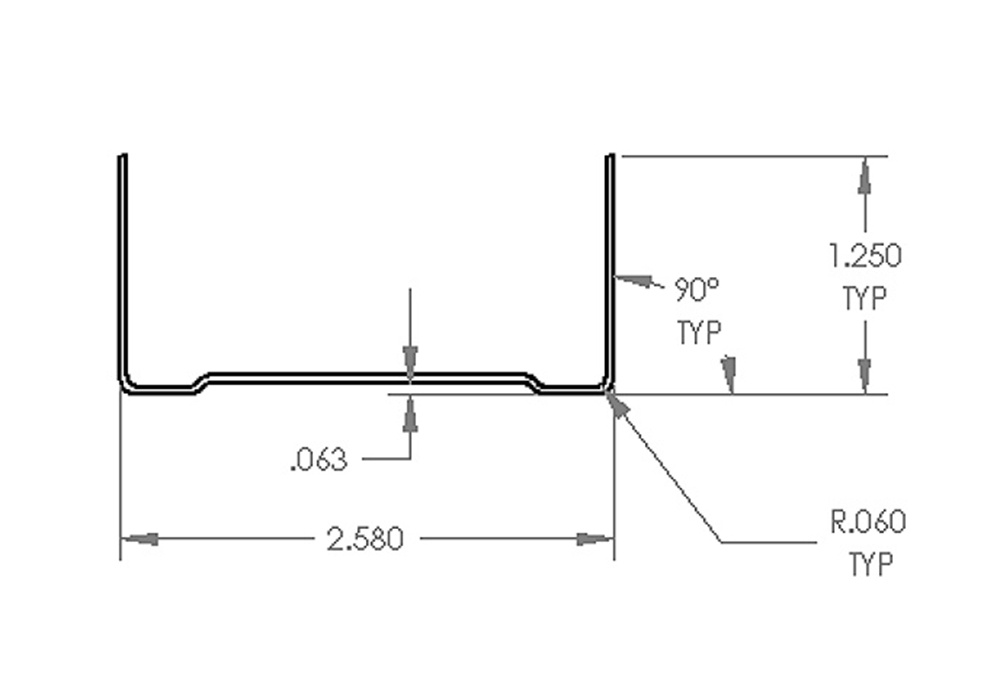

S41 x0.50

-

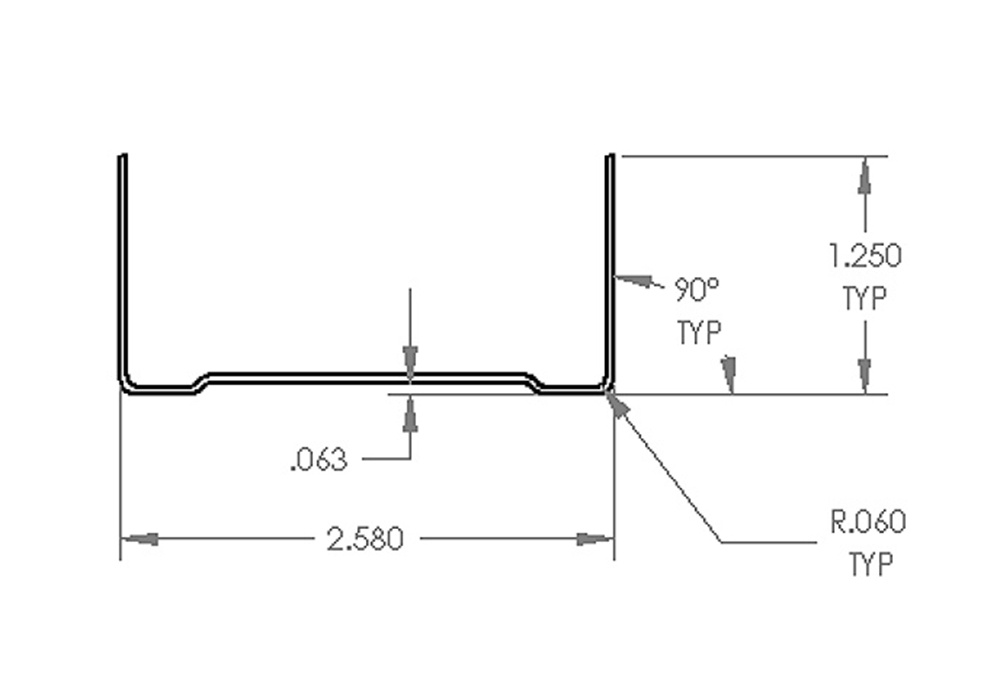

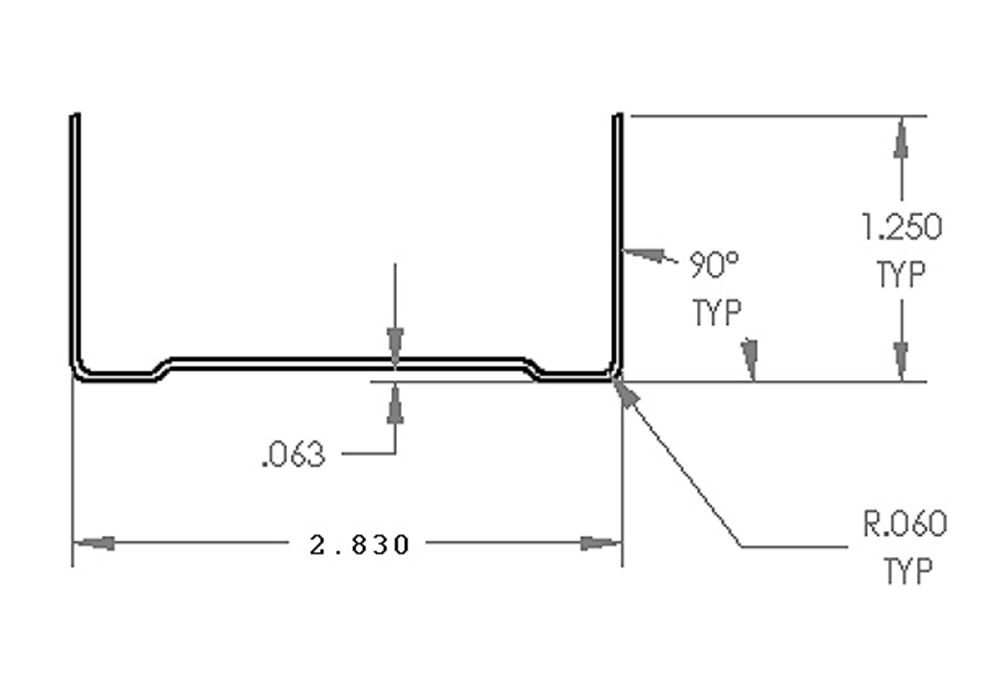

S64 x0.50

-

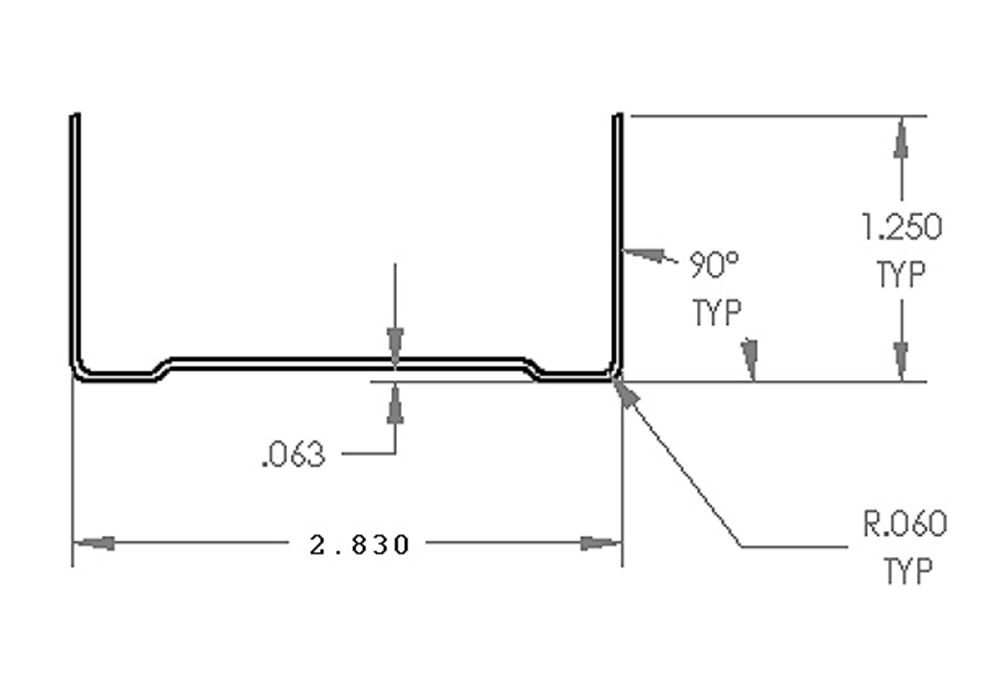

S70 x0.50

-

S92 x0.50

-

A. Main data

1.Material thickness(mm):1-2.0mm, Max feeding width:1200mm. Material:GI, AL

2.Roller QTY:16 groups.

3.Install type:Column type with gearbox drive

4.Roller form:According to the customer

5.Roller material: GCr15(ball bearing steels)quenching treatment. Surface is hard chrome plating, HRC58°-62° Depth of quenching :8mm

6.Main shaft material: High quality 40cr thermal refining with surface hard chrome plating.

7.Drive mode:Cycloidal pin gear speed reducer, Motor power:22KW

8.Working speed:0-15M/min

9.Hydraulic station motor power:7.5KW

10.shear mode:Hydraulic cutting, profile cutter

11.Die and blade material:Cr12mov (3 sets cutting blades)

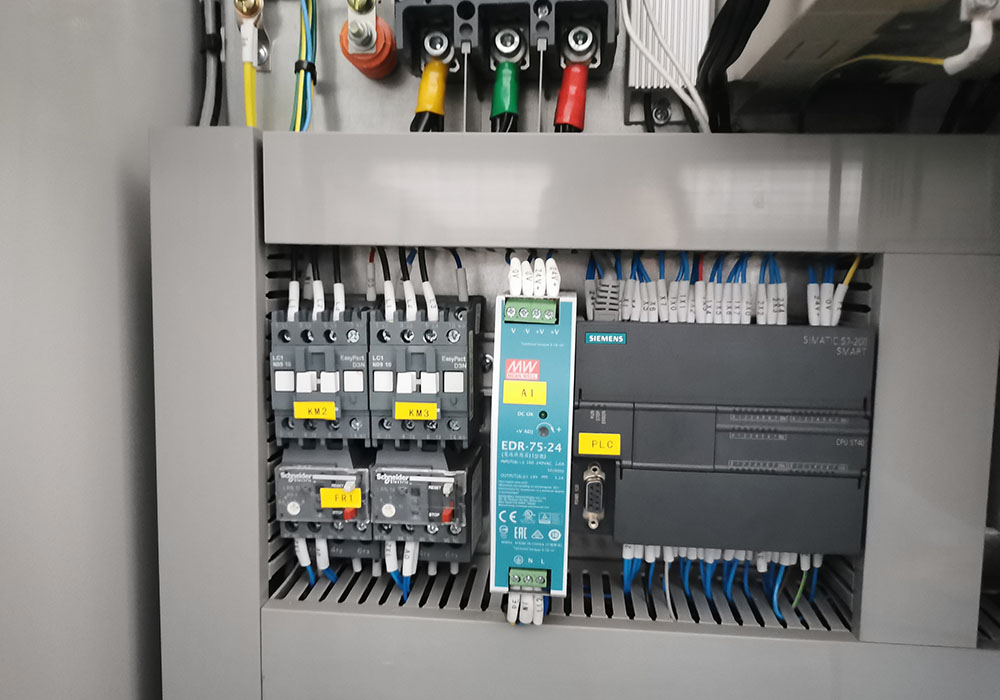

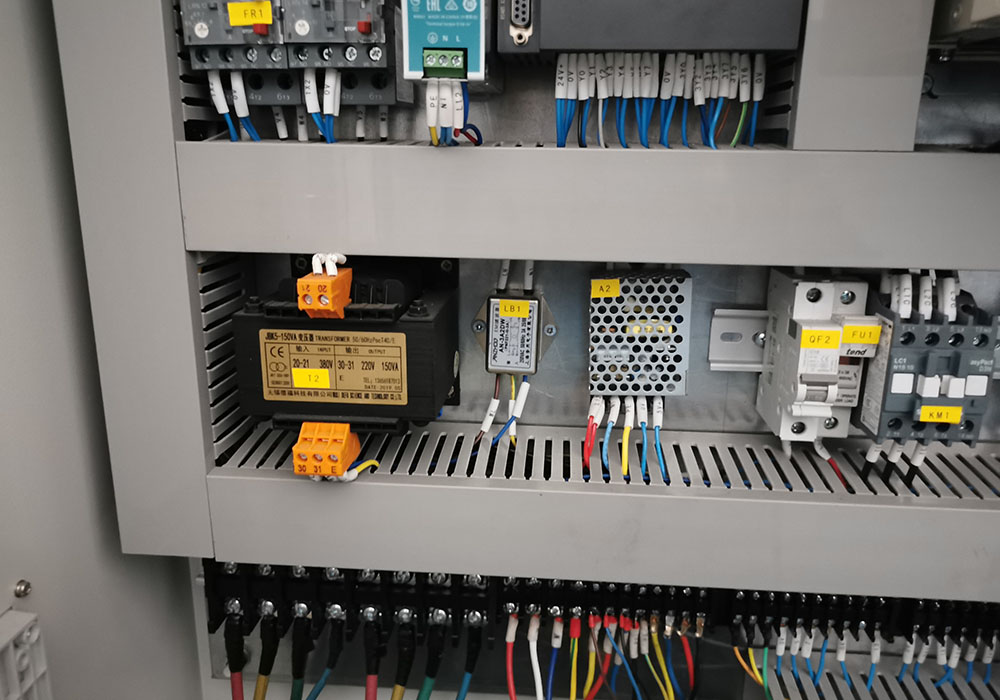

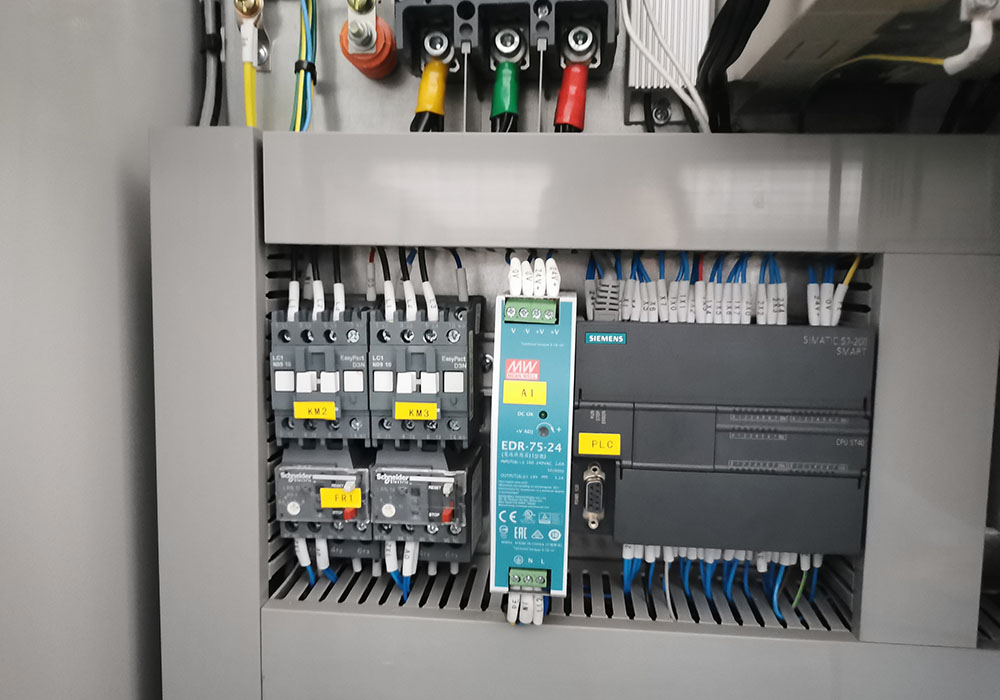

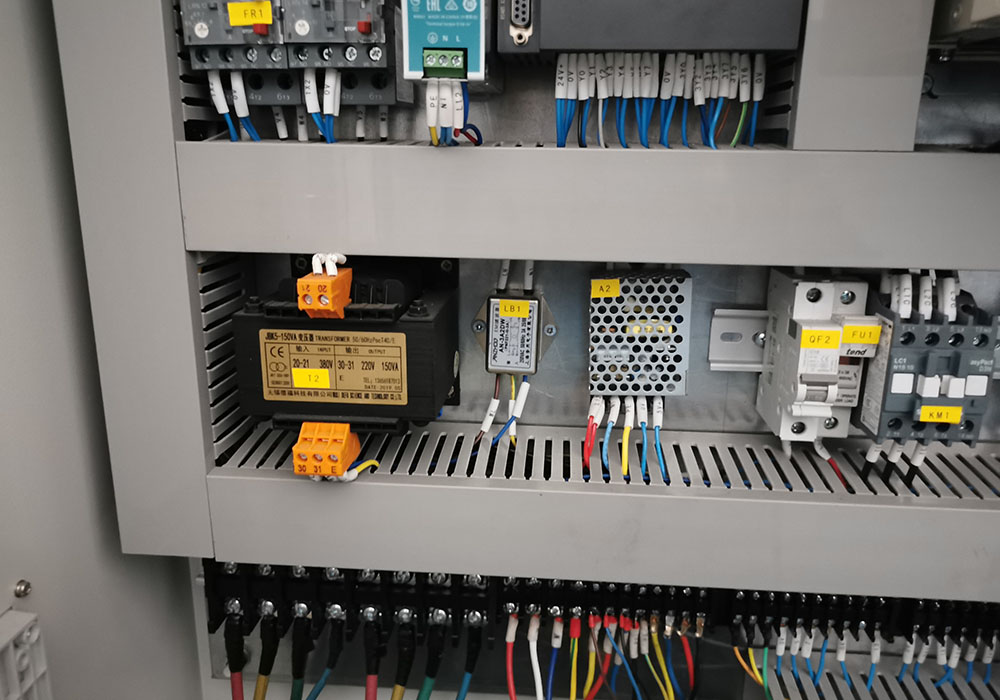

12.Electronic system:Industrial computer Siemens PLC、YASKAWA frequency converter、Omron encoder、Schneider brand low voltage apparatus

13.Dimension of the machine:12m×1.1m×1.5m

B.Structure and features1.Quick change the remodel, C shape steel all kinds of specifications realize automatic computer electrodeless remodel, exchange the profile time is only 5 mins. It break the traditional type, using left side fixed mode.

2.Adjustable, CU100-600 cable tray roll forming machine can be adjusted in any dimension with the the range, for example web, flange, and flange lip can be adjusted in mm unit.

3.The machine use automatic and manual adjustment to make C/U shape. It is no necessary to change the roll if need to change the profile. During the producing, it uses automatic control mode, which can do automatic punching, cutting and forming according to the length and QTY of the cable cap.

4. CU cable tray roll forming machine is including guide device, level device, roll forming machine, hydraulic cutting machine, carrier device, electronic system, hydraulic system, etc.

C. Production technology process

10T Hydraulic feeder →level and feeding→forming→hydraulic cutting→output

-

Electric system

-

Electric system

-

Electric system

-

Electric system

-

Electric system

-

Electric system