-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Two and Three Waves Guardrail Roll Forming Machine

Two and Three Waves Guardrail Roll Forming Machine

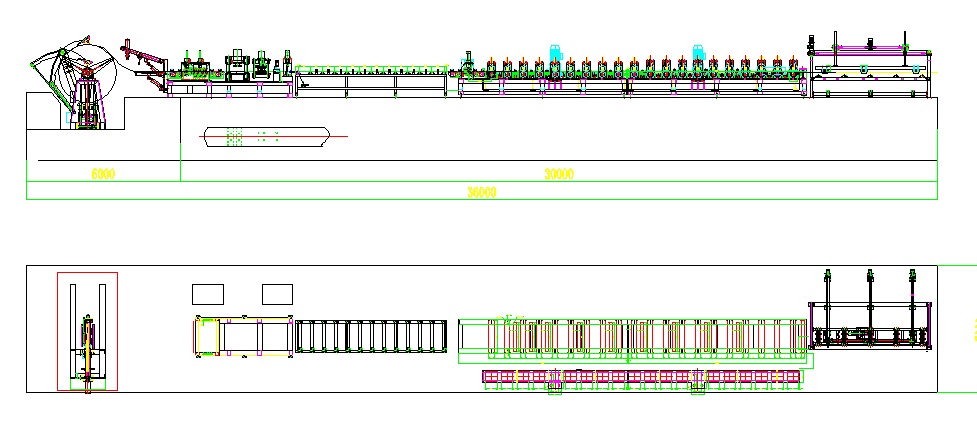

Two waves and three waves highway guardrail roll forming machine Description

We are the professional manufacturer of making the guardrail roll forming machine in China. We export this kind of machine to a lot of countries, this can of machine can make two waves or three waves profiles according to your demands, for this kind of line, we can give you different solutions on the basis of different requirement.

For this kind of guardrail, the normal thickness of the material is 3.0mm, some are 3.5mm. The mean application is separation, blocking, warning function, etc. The configuration of two waves and three waves machine is different from the two waves machine, please contact me if you want to learn more details of the whole line. We also can make the automatic stacker for the end product which can improve the efficiency of worker.

Two and three waves Guardrail roll forming machine (Heavy duty)

A.Technology Process

Hydraulic feeding→press head and shovel head→Guiding feeding→Level machine→ punching and cutting→transfer table→forming→output

Main data

1/ Q345BRaw material mechanical property and Spec.: Q345 B steel strip

2/Steel strip thickness:: 3.0-4.2mm

3/ The width of the strip:350-750mm

4/Steel coil bore: φ500-620mm

5/Precision of the work piece:Length±1.0mm,hole distance±1.0mm,straightness 0.5mm/M,width tolerance±3mm,punching location degree tolerance:≤0.5mm;degree of symmetry±1.5mm;

6/ LXWXH:about 35m×3m×2.6m

7/ Worker quantity: 2 workers

8/ Total power of the line:about 90KW

The machine is including 10T hydraulic decoiler, leveling device, plate punching, Pre-cutting device,6M automatic conveyor, roll forming machine, Automatic stacker, hydraulic station, PLC system etc .

Main parts description

1.Hydraulic decoiler

Function:

Structure: The decoiler is including the 10T feeding device, rack, supporting device, feeding device, press head, load car, electric system, hydraulic, shovel head, straight head device, etc.

1.1、Feeding car: Put the steel coil on the V shape working table, hydraulic cylinder drive the hoisting appliance to make the steel coil go up to the central position of the expand shaft, feeding car go along the guide rail of the foundation, the gear motor drive to do the lateral displacement.

1.2、The coil via hydraulic cylinder to drive and expanded, press head press the coil tightly, hydraulic motor traction the coil rotate to turn loose the coil. The press head is formed by 3KW motor.

1.3、Shovel head and straight head device: After turn loose the coil, using shovel head and straight head device, and the upper pinch roll device to make the head of the coil straight, which is easy to feed.

1.4、The decoiler is with side roller to prevent the coil flex. Roller diameter and length can meet the requirement, which can guarantee the different size coil to tight.

Technology data:

Dabber harmomegathus range:φ500-620mm

Max width of the coil:about 450mm

Max OD of the coil:1500mm

Max loading capacity:8T

Thickness:2-4mm

Feeding car:Lifting stroke 500 ,Travel stroke 2000

2.Clamping and leveling device

Leveling machine is using four-wheel guiding, two roller feeding, seven rollers levelling, using transmission case to transmit the power. Four-wheel guide which put the material on the scheduled the position to guide. The machine function is that it can let the coil level when the coil is moving ahead. The machine power is 7.5KW, and power come away when the machine is working normally.

3.Servo feeding and punching machine and pre-cutting

Function:Punching

Structure:Servo feeding machine and gantry type three groups punching die. It can meet the drawing requirement. Servo motor and brand: YASKAWA motor 5.5KW.

Punching machine is Stand column gantry type frame structure, it set up multi-hydraulic cylinder and die.

The punching die front opening is effective and easy to change the punching pin.

The punching die is in up stroke, it can self-lock, and no glide after the machine stop.

For reducing the shaking force and hydraulic system pressure during the punching, we use grading punching.

Punching die material: Punch die use SKH51or DC53(equal to SKD11)die steel with forging and accurate grinding. HRC58-62.

Punching die repeated use mode: the punching die can strike , sharpening and can repeated use.

The punching die is ball-lock type. It is easy to change.

Technology data:

Punching speed: 3-4 sec/rate

Thickness:3.0-4.2mm

Material:Q345B Steel strip

Pre-Cutting machine

Function :Cutting

Structure :The machine is including portal frame, up and down guiding device,blade install plate, blade, cylinder, etc.

Cutting power:Hydraulic cylinder drive

Blade:shape blade, the material is Cr12MoVdie steel,HRC58-62。

The blade working life is more than 100000 times.

4.Roll forming machineFunction and structure: separate memorial archway

Drive mode:Oblique tooth surface reducer→gear box transmission case→cardan joint→roller

Dimension of the roll forming machine: 12m×2m×1.3M(LXWXH)

Material thickness: 3.0-4.0mm

The roll forming machine is including two groups quick-change structure, one group is used for two waves profile, the other one is used for 3 wave profile. To crane the roll forming machine when it doing quick-change. Using the same frame and power and PLC control system.

The part of roll forming machine is up and down drive, for reducing the speed-difference internal friction caused by section changing, some roller shaft is used single drive.

The front first, second roller and the last roll of the line are used down up and down roller drive, others used down drive.

Technology data:

Memorial archway material: ZG45 one take, no need to weld

Roller material: GCr15bearing steel with hot forging and finish machining, HRC58—62

Roller step:2-wave 14 steps,3-wave 20 steps

Die-filling width:400mm

Big shaft diameter:φ110mm

Motor power:45KW

5. Stacker

Function: stacker

Take up proposal use “double lifting two-position stacker”

Double lifting device is including the motor, worm-gear speed reducer, lead screw, stacker table, etc.

Two electromagnetic chuck, according to the electric system to receive the material.

Blank machine is including blank plate, crank connecting rod, drive cylinder and rack, etc.

Two-position movement device is including motor, reducer, platform trolley, chain wheel, guide rail and linkage device, etc. The stacker have the function of double lifting automatic displacement, automatic change the position, etc. stacking height is about 800mm.

The length is : 4M

-

Electric system

-

Electric system

-

Electric system

-

Electric system