-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Downspout Roll Forming Machine

Downspout Roll Forming Machine

Downpipe apply to rainwater goods system. Thickness of gutter is 0.4mm-0.8mm, 0.8-1.5mm, raw material: Aluminum, Galvanized steel, Painted steel, Galvalume, Stainless steel etc. We could offer you square pipe roll forming machine (rectangular downspouts roll forming machine) and round pipe roll forming machine (round corrugated downspouts roll forming machine) also a separate elbow machine. We also can make the AIO machine, that is to say, forming and bending on one machine, it will help you to improve the production efficiency and the labor cost.

In rainwater goods system, we are able to manufacture more machines like water gutter roll forming machine, etc.

We can make different solutions according to your requirement and drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need.

Main data

1.Material(㎜):Width:About 445mm,Thickness 0.23-0.4mm,Yield strength ≤550MPa。

2.Working speed:10~15M/min(Not including the cutting time)

3.Roller steps: 24 steps

4.Main motor power:7.5KW Servo motor Chain drive

5.Hydraulic station motor power:11KW, Pressure of hydraulic station:10~12 Mpa

6.Roller material:High quality 40Cr forged steel with finish machining and quenching treatment. Hard chrome on surface

7.Main shaft material:High quality 45# steel with thermal refining treatment

8.Shaft diameter:φ76mm

9.Cutting mode:Hydraulic cutting after forming

10.Blade material:Cr12Mov with quenching treatment HRC58-62°

11.Drive mode:Chain drive

12.Tolerance:width-/+0.5mm, height-/+0.5mm,length -/+1.5mm

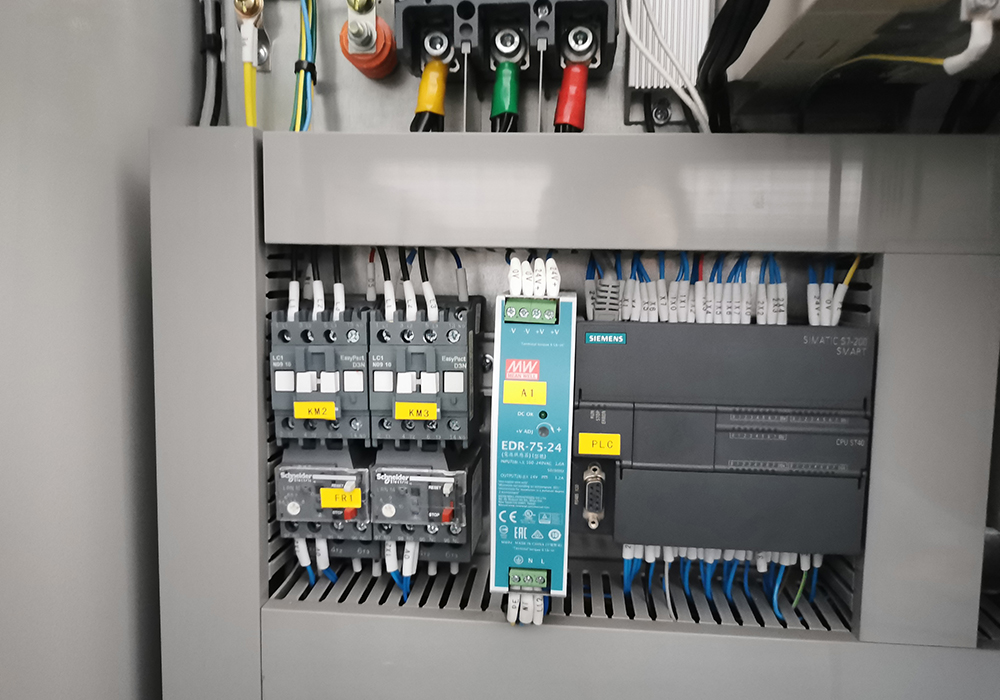

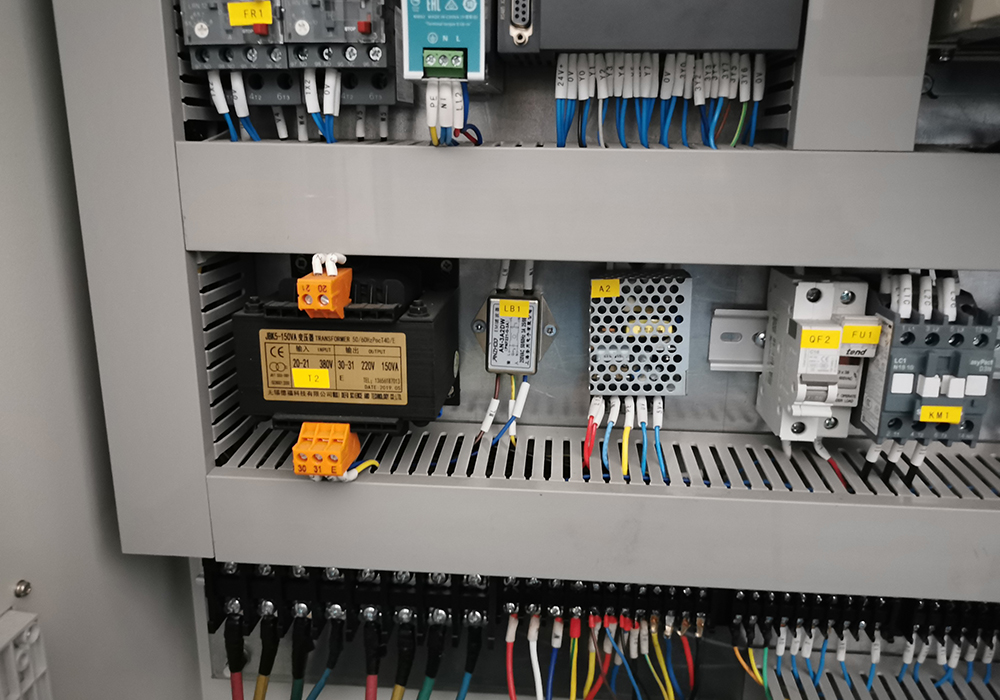

13.Electronic system:Siemens PLC to control the whole line, YASKAWA frequency converter.

14. We install the mesh safety protective cover on the machine.

Machine Structure

The machine is including 3T manual decoiler, drive device, roll forming machine, pinch device after forming, bending device after forming, cutting and necking down device, hydraulic system, electronic system, output table.

Production technology process

Feeding → adjusting → forming → Pinch after forming → Bending, cutting and necking down after forming → output