-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

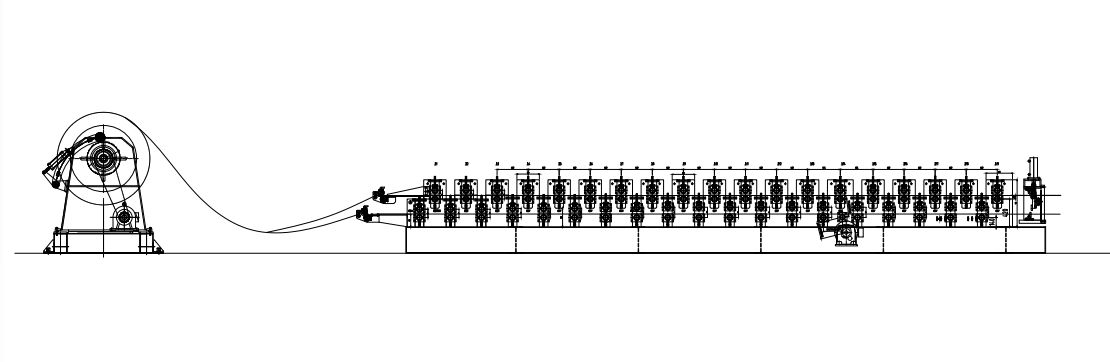

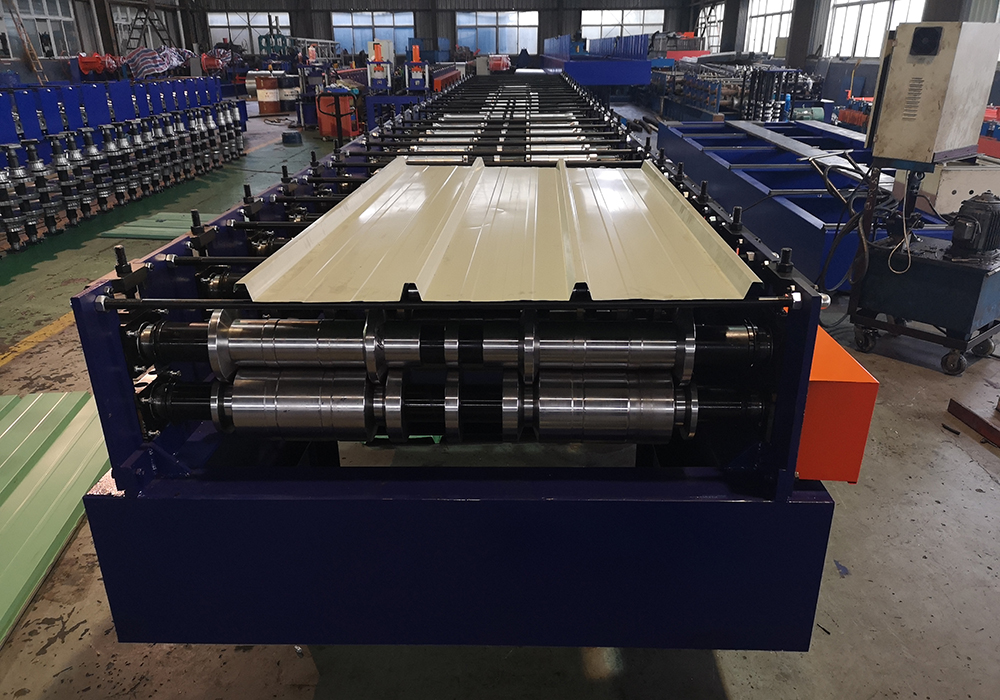

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

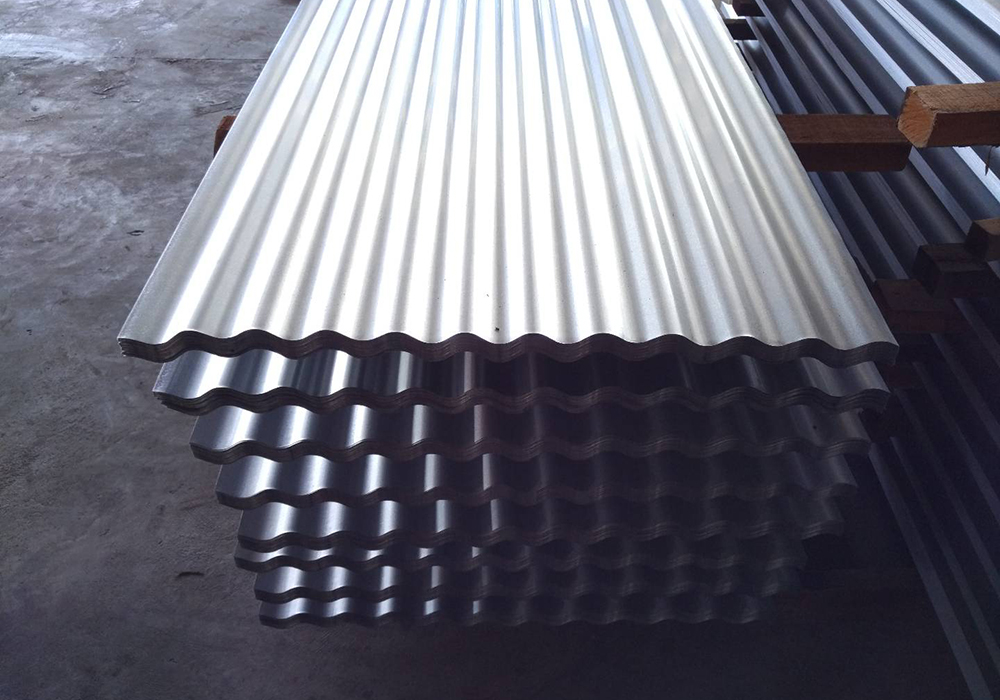

Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

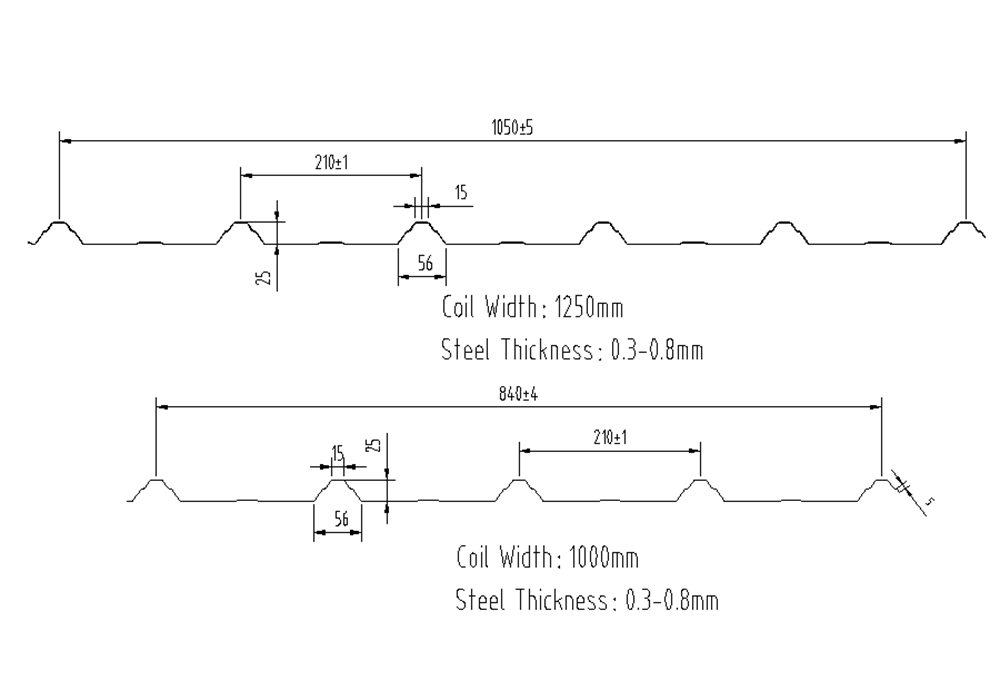

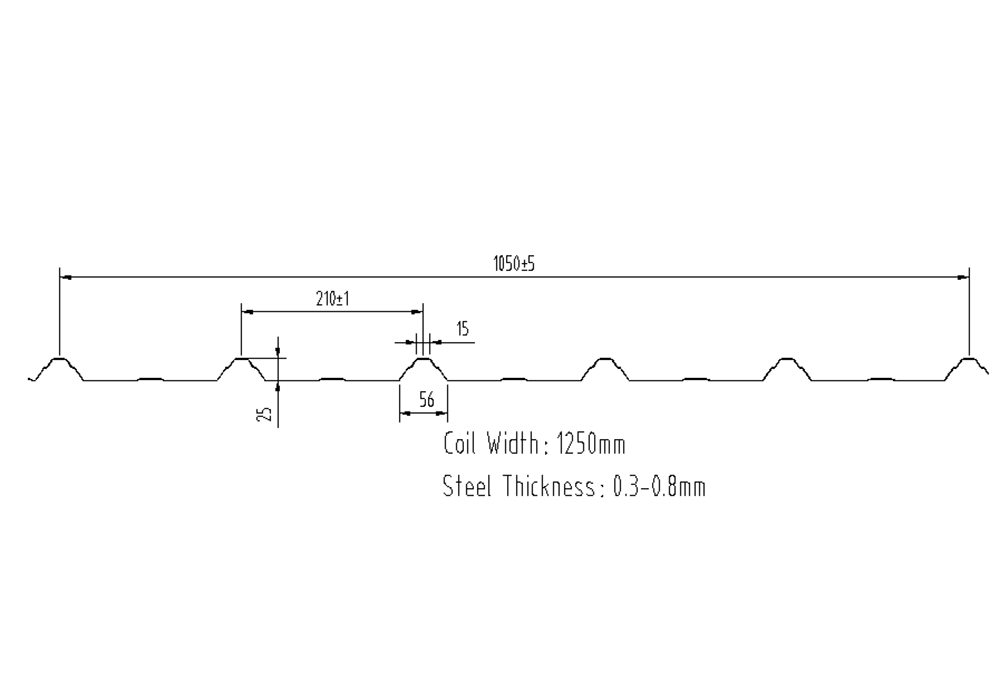

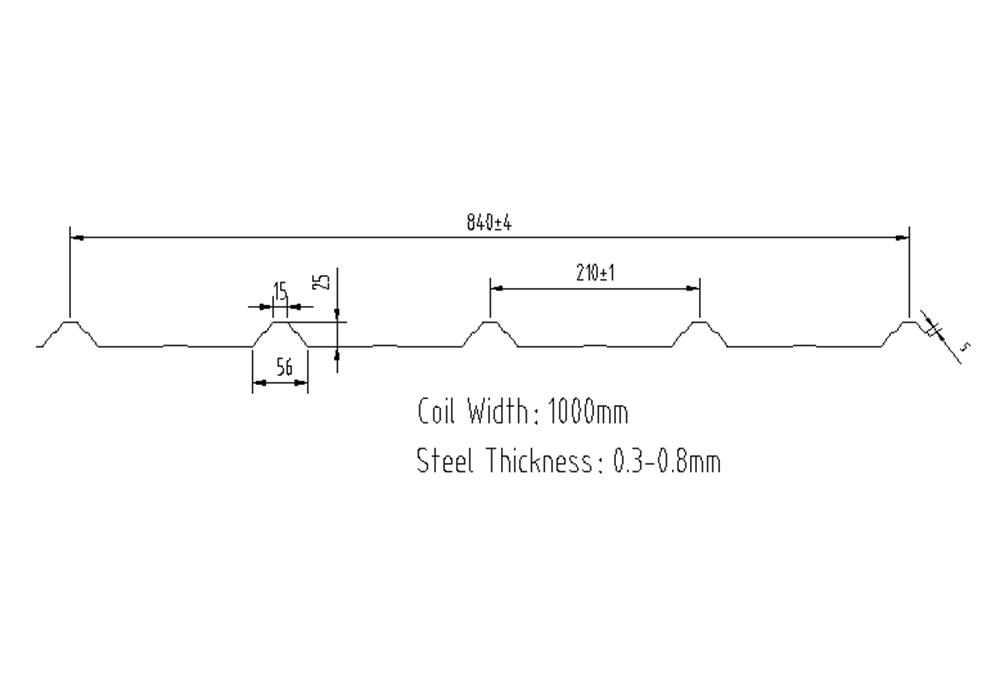

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more space and money of course more economy compared with two different machines.

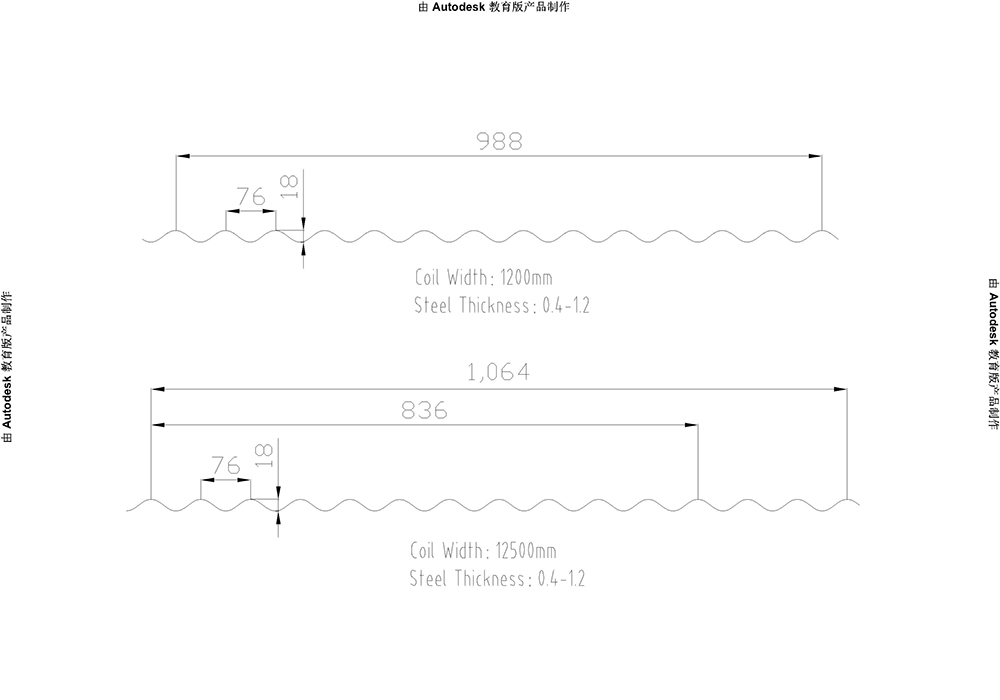

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

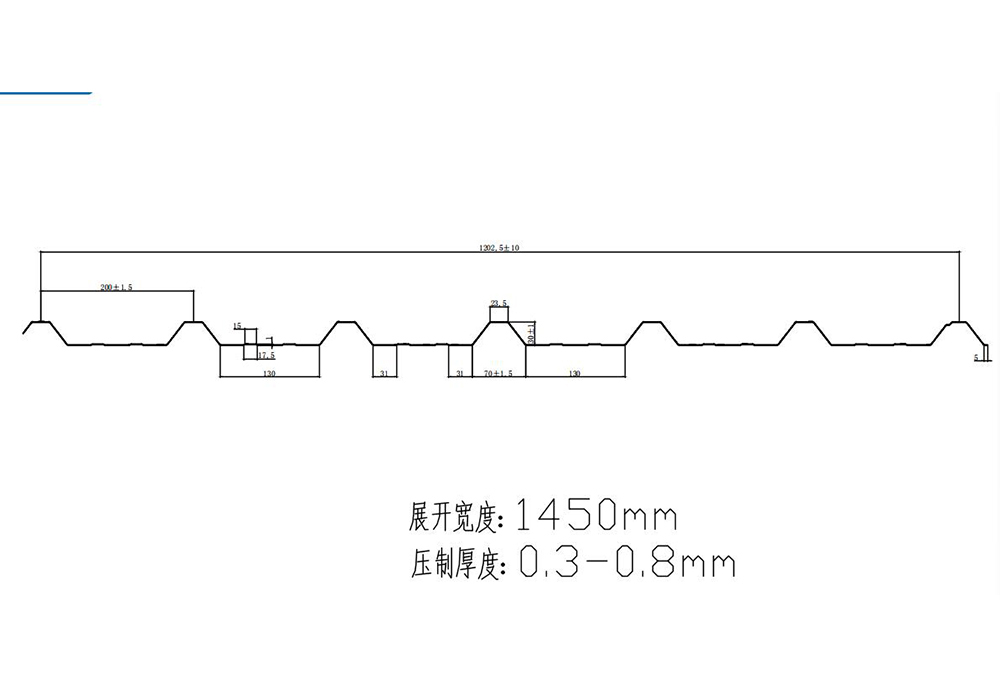

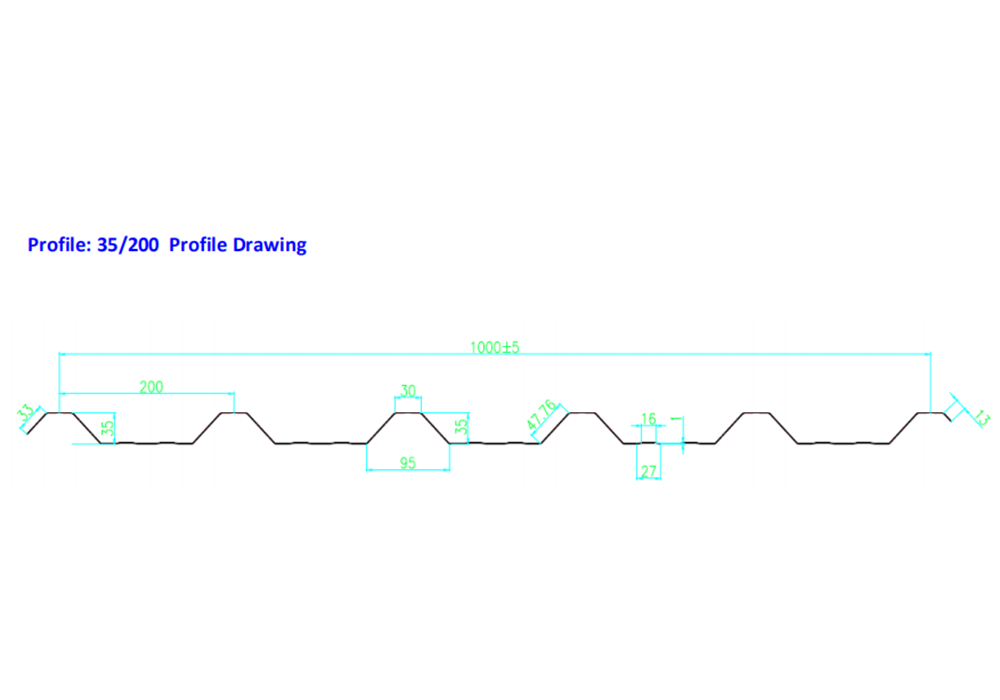

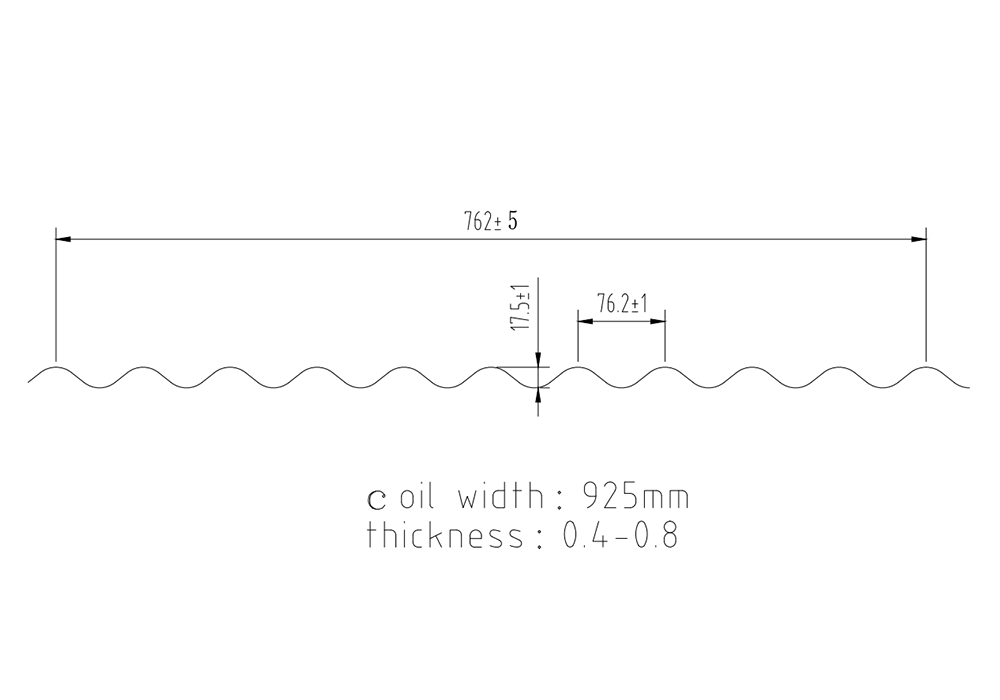

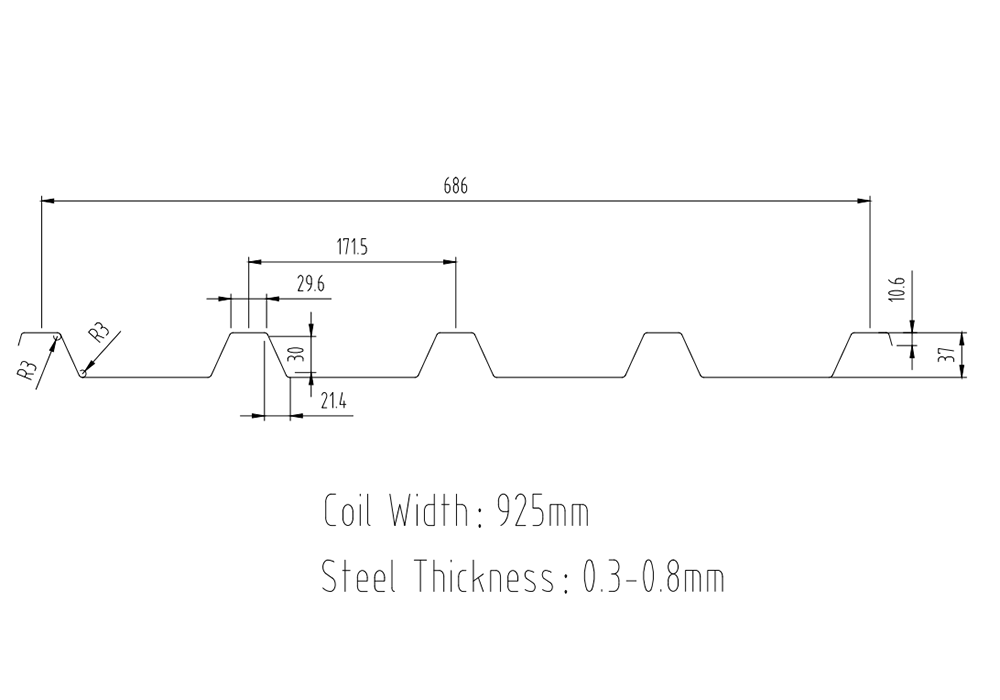

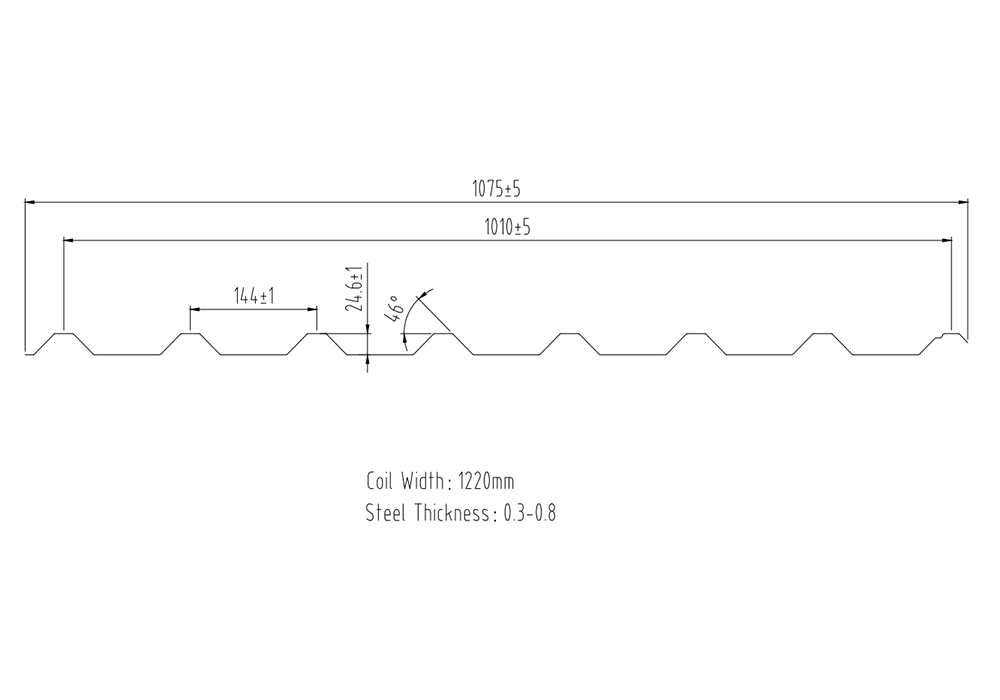

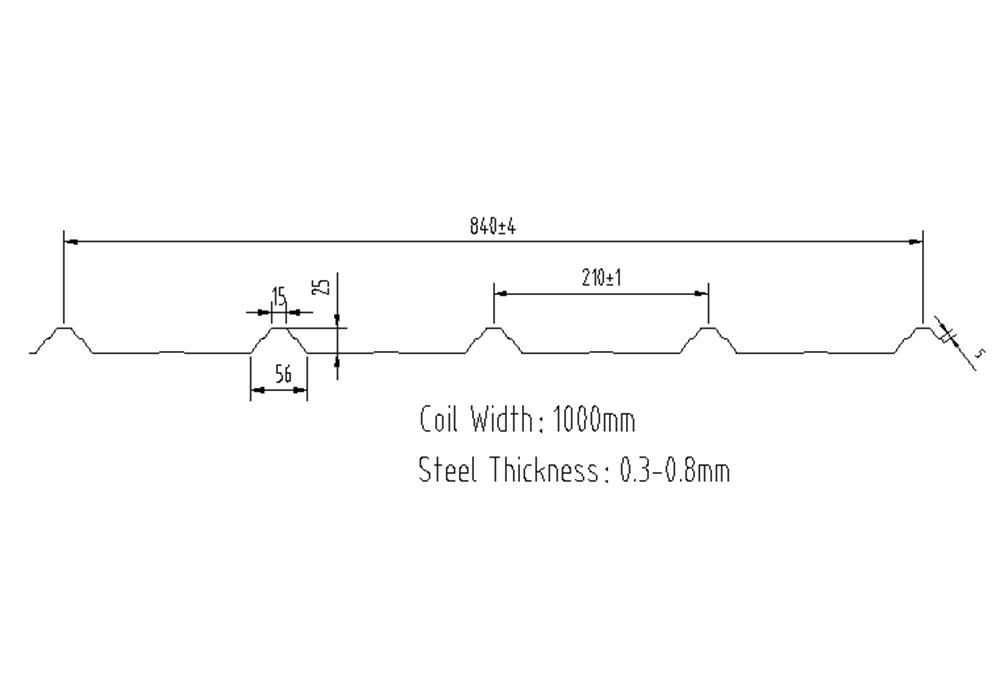

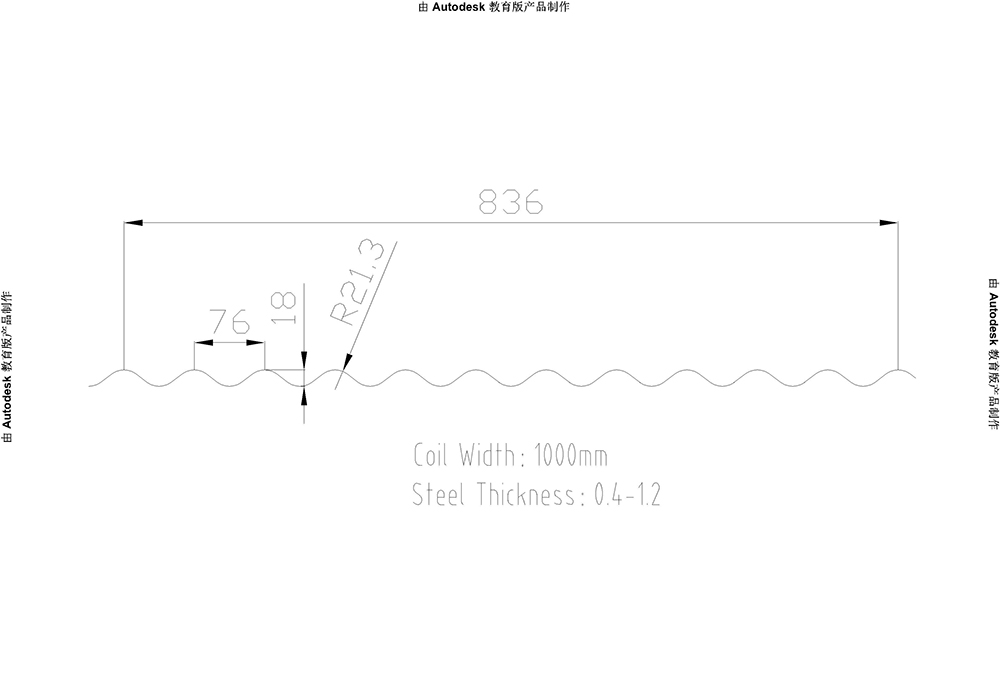

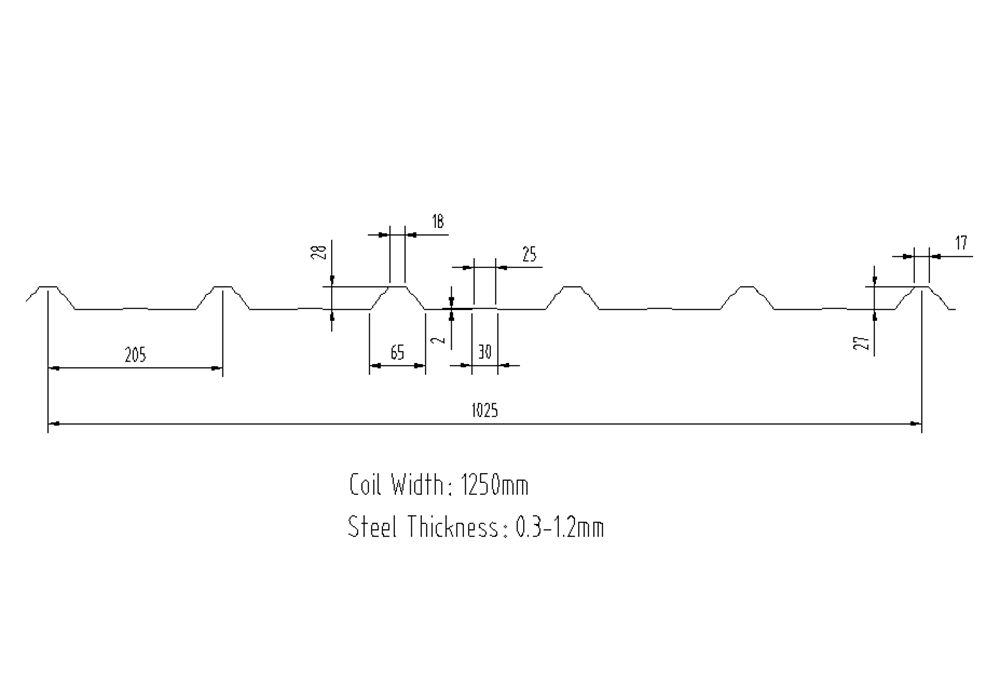

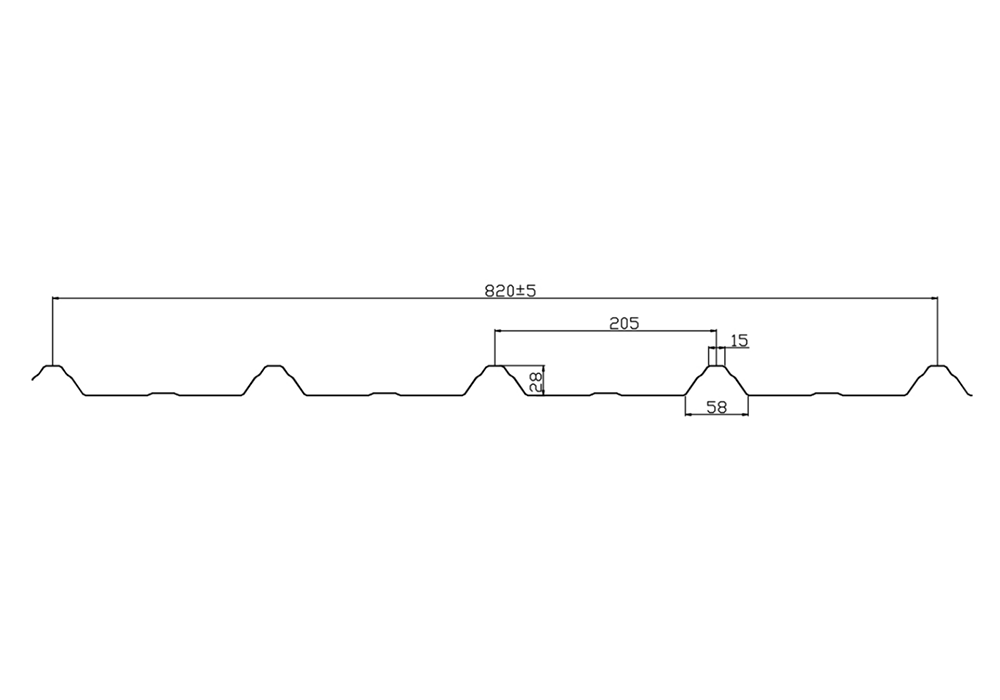

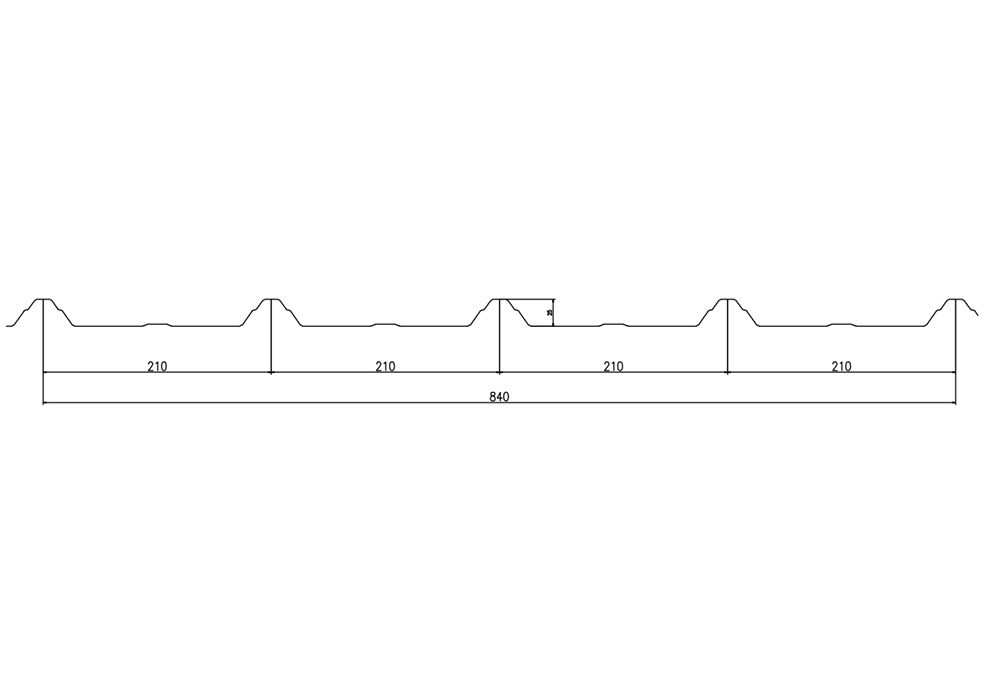

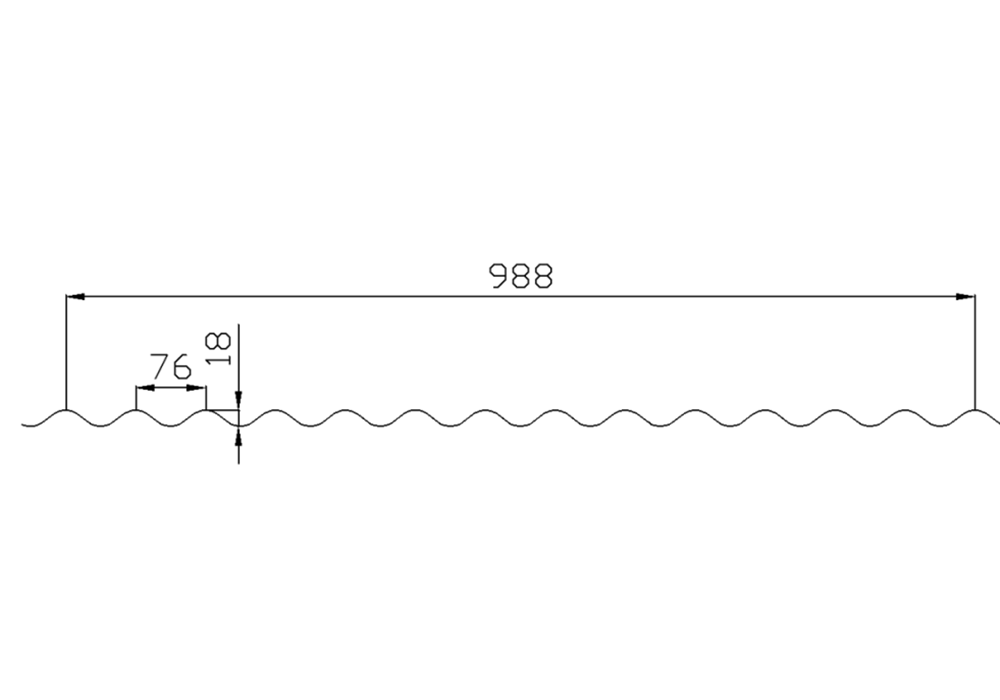

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed can reach about 20M/min, if the capacity is big, we can make the machine speed which can reach 25-30M/min. And some customer they require the thickness of the roofing sheet is 1.2mm, it is ok too. If you want learn more of this kind of machine, choosing our company is your best option.

A. Main data

|

No. |

Item |

Spec |

Unit |

|

1 |

Machine Type |

Double layer |

|

|

2 |

Structure |

Wall board type |

|

|

3 |

Raw material |

PPGI |

|

|

4 |

Feeding width |

/ |

mm |

|

5 |

Effective width |

838/1045 |

mm |

|

6 |

Thickness |

0.3-0.8 |

mm |

|

7 |

Yield strength |

350mpa |

Mpa |

|

8 |

Working speed |

15-20 |

m/min |

|

9 |

Roller QTY |

20/22 |

step |

|

10 |

Roller material |

45# forget steel and chroming plate on the surface |

|

|

11 |

Main shaft material |

45# high quality steel, quenching treatment |

|

|

12 |

Diameter of the shaft |

75 |

mm |

|

13 |

Main motor power |

7.5 |

KW |

|

14 |

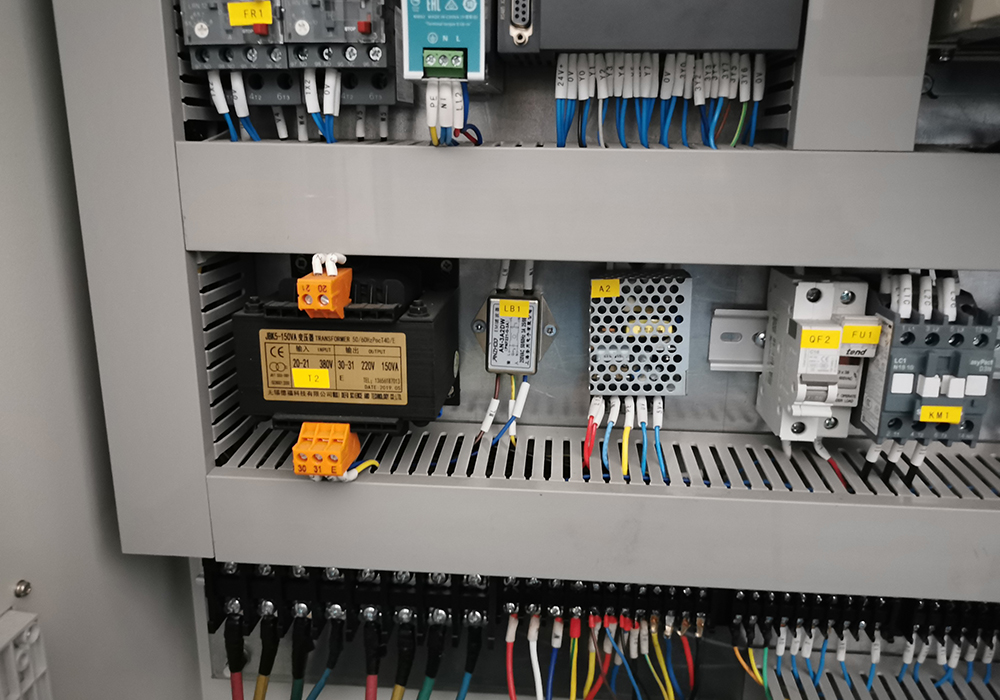

Hydraulic station power |

3 |

KW |

|

15 |

Hydraulic pressure |

12 |

Mpa |

|

16 |

Voltage |

According to the customer requirement |

|

|

17 |

Blade material |

Cr12 quenching treatment |

|

|

18 |

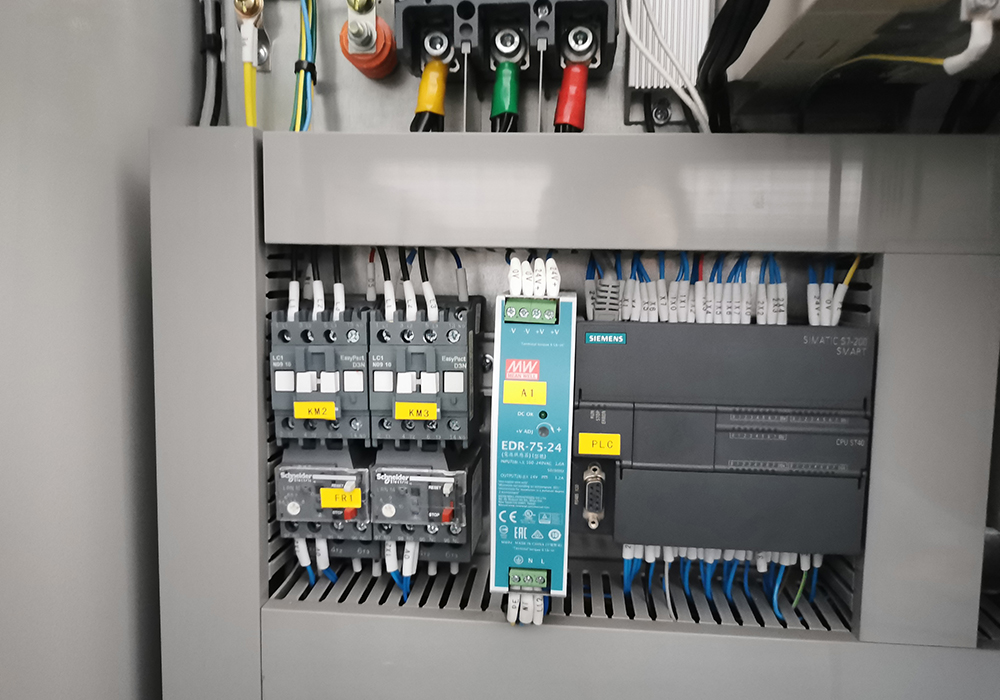

Electric system |

Siemens PLC |

|

|

19 |

Cutting mode |

Hydraulic cutting, cutting after forming |

|

|

20 |

Color |

Blue+yellow |

|

|

21 |

Container dimension |

1x40 |

GP |

B. Machine structure

Double layer roll forming machine is including 5T manual decoiler, drive system, roll forming machine, cutting device, hydraulic system, electric system, and output table, etc.

C. Production technology process

Feeding → Leveling → forming → cutting → output