-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine

Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

Glazed tile Roll Forming Machine can produce different profile drawings according to your requirement, there are a lot of different kinds of profiles of the glazed tile, so when you want to know more about this kind of machine, please also send me the profile for reference, that would be better.

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed is about 0-8M/min. If you want learn more of this kind of machine, choosing our company is your best option.

Main data

1.Feeding width(㎜):1200mm

2.Working speed:0--8 /min

3.Roller step:14 steps

4. Rack: 350H Steel welding

5. Shaft diameter:¢75mm, 40Cr with thermal refining and do second machining, and grinding.

6. Chain:1 inch, single row

7. Motor power of roll forming machine:7.5KW

8. Roller material:High quality steel with forging. Surface is hard chrome plating.

9. Hydraulic station motor power:5.5Kw

10. Hydraulic station oil pump:gear pump

11.Cutting mode:Hydraulic cutting

12. Blade material:Cr12Mov

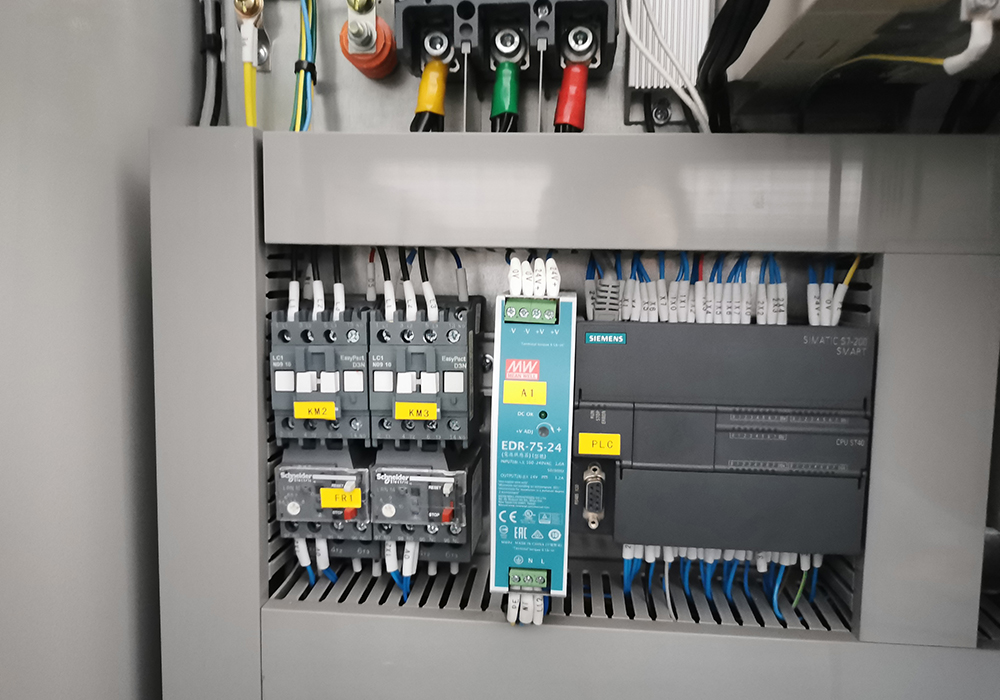

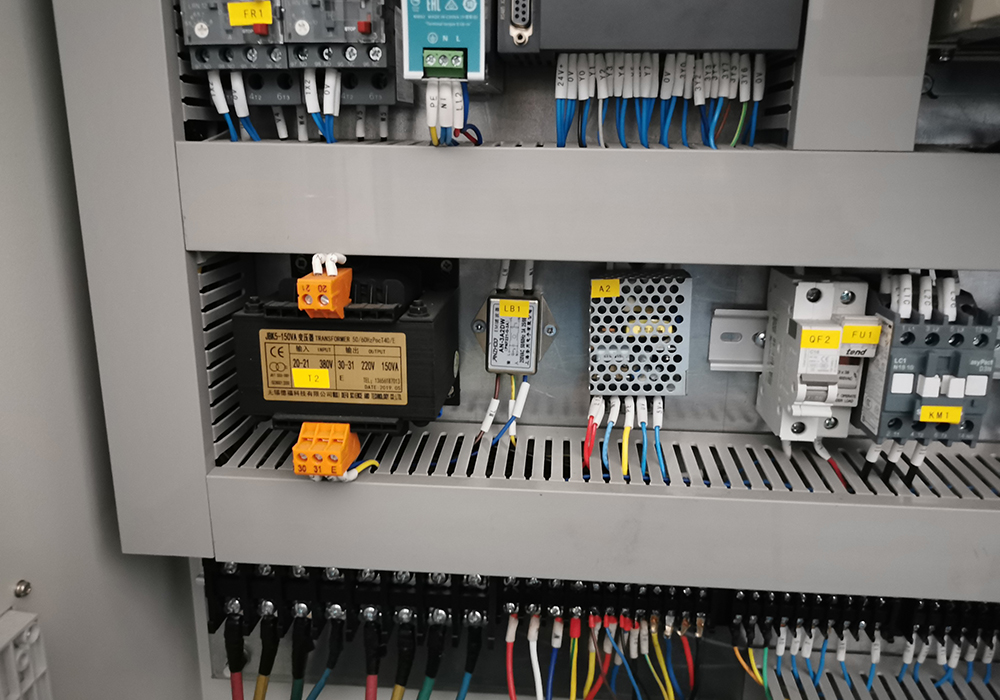

13.Electronic system:Siemens PLC system.

Main structure and features of the machine

1、Main features:

a、Simple structure, nice exterior, because of the machine using steel structure, overall machining after welding, so the structure is concise and reasonable, loading capacity is good, the machine running is steady and reliable.

b.The other important spare parts , using domestic famous brand,and guarantee the machine quality

c、Our machine use automatic fixed length ,forming, punching, length and location is accurate, the profile end to end is beautiful and orderliness, is not out of shape.

d、The machine installation and commissioning is easy, it is not only can running in the factory, but also can move to the job site to work.

2、Machine Structure

glazed tile roll forming machine is including 5T manual uncoiler, drive system, roll forming machine, punching die, cutting machine, hydraulic station, electronic system, output table,etc.

Production technology process

Feeding → Feed into the sheet → Leveling → forming → punching → cutting → output