-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

Layer board roll forming machine

Layer board roll forming machine

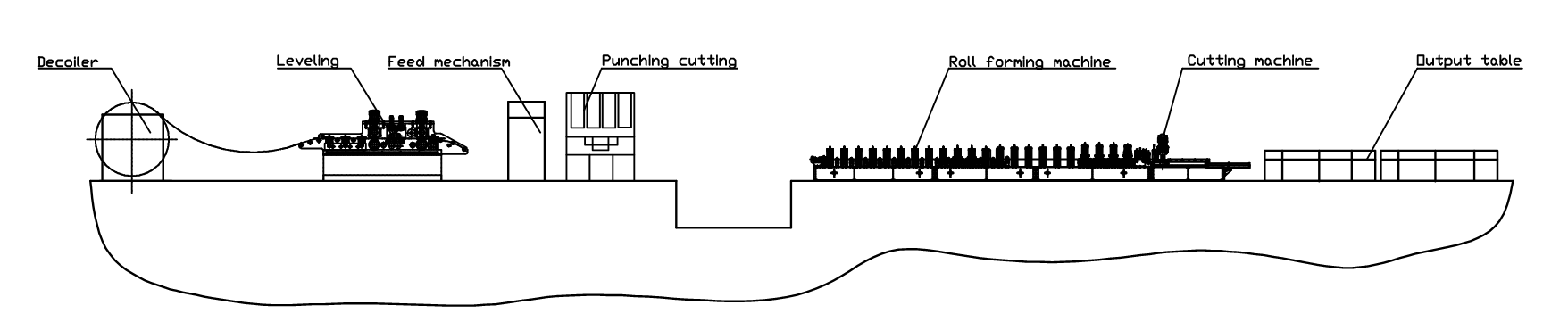

The whole line includes the decoiler, roll forming machine, cutting blade, automatic conveyor, re-forming machine, output table , electric system, etc. Please contact us if you want to learn more details of this kind of machine.

A Main data

No. |

Item |

Specification |

Unit |

|

1 |

Machine Type |

Special shape |

|

|

2 |

Structure |

Column structure with gearbox drive |

|

|

3 |

Raw material |

Galvanized steel coil |

|

|

4 |

Feeding width |

/ |

mm |

|

5 |

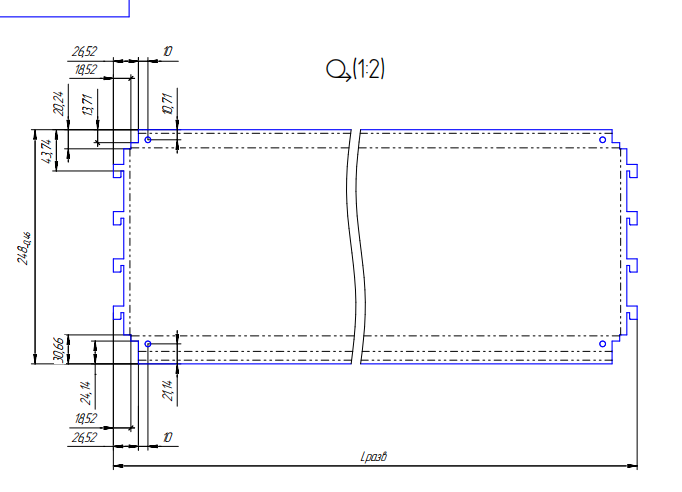

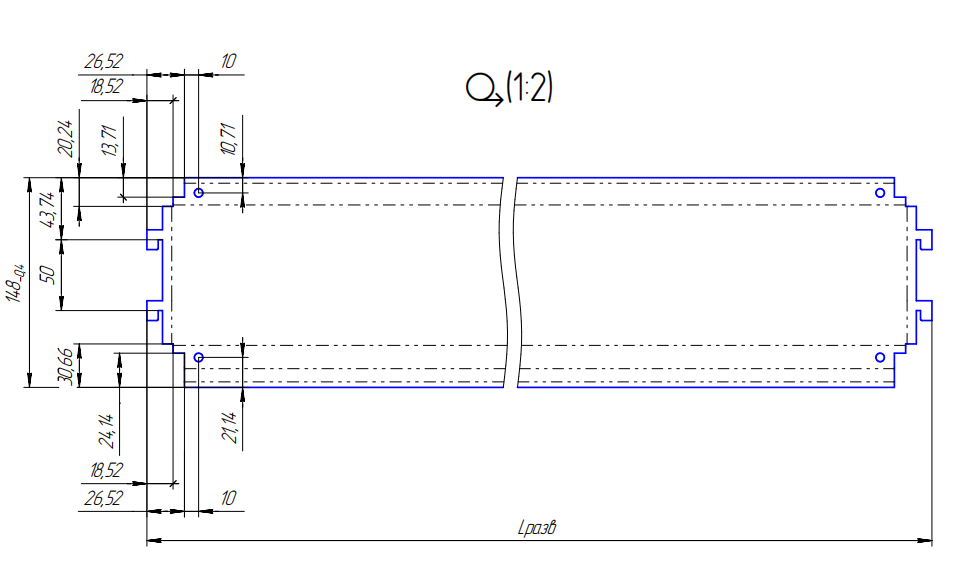

Effective width |

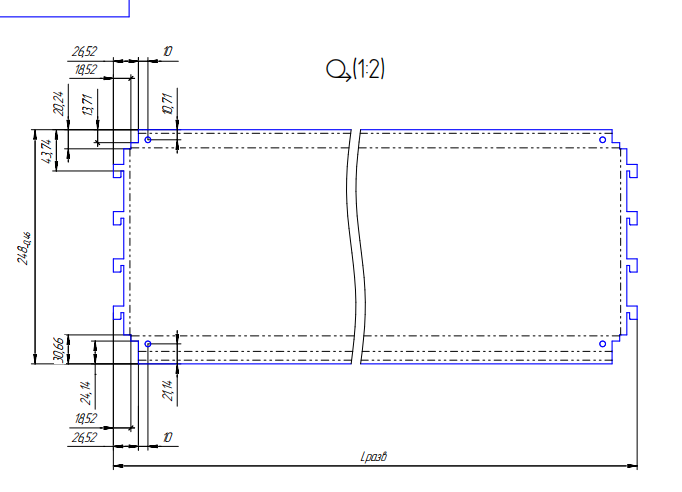

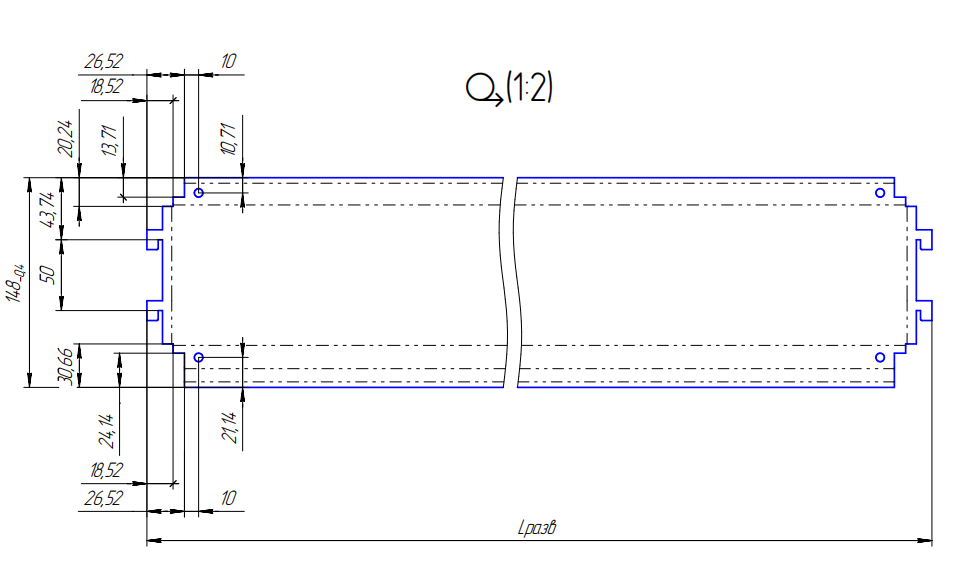

248/148 |

mm |

|

6 |

Thickness |

0.8 |

mm |

|

7 |

Yield strength |

350 |

Mpa |

|

8 |

Working speed |

10pcs/min |

m/min |

|

9 |

Roller QTY |

16 |

Tep |

|

10 |

Width adjustment |

Automatic adjustment |

|

|

11 |

Roller material |

GCr15 with hard chroming plate, HRC58-62° |

|

|

12 |

Main shaft material |

40Cr, with thermal refining treatment |

|

|

13 |

Diameter of the shaft |

60 |

mm |

|

14 |

Punching system |

Hydraulic punching system |

1 set |

|

15 |

Punching moulds |

4 sets |

|

|

16 |

Main motor power |

7.5 |

KW |

|

17 |

Hydraulic station power |

4 |

KW |

|

18 |

Hydraulic pressure |

12 |

Mpa |

|

19 |

Voltage |

According to the customer requirement |

|

|

20 |

Blade material |

SKD11 |

|

|

21 |

Electric system |

Siemens PLC |

|

|

22 |

Cutting mode |

Hydraulic cutting, cutting after forming |

|

|

23 |

Color |

Blue+yellow( or customized) |

|

B.Machine structure

C section roll forming machine is including 3T manual decoiler, drive system, roll forming machine, punching mould, cutting device, hydraulic system, electric system, and output table, etc.

C. Production technology process

|

Feeding  Leveling

Leveling pre-punching

pre-punching forming

forming  cutting

cutting  output

output

|

D profile

|