-

tel: +86 18961855618

-

email: vivian@zcmachinery.com

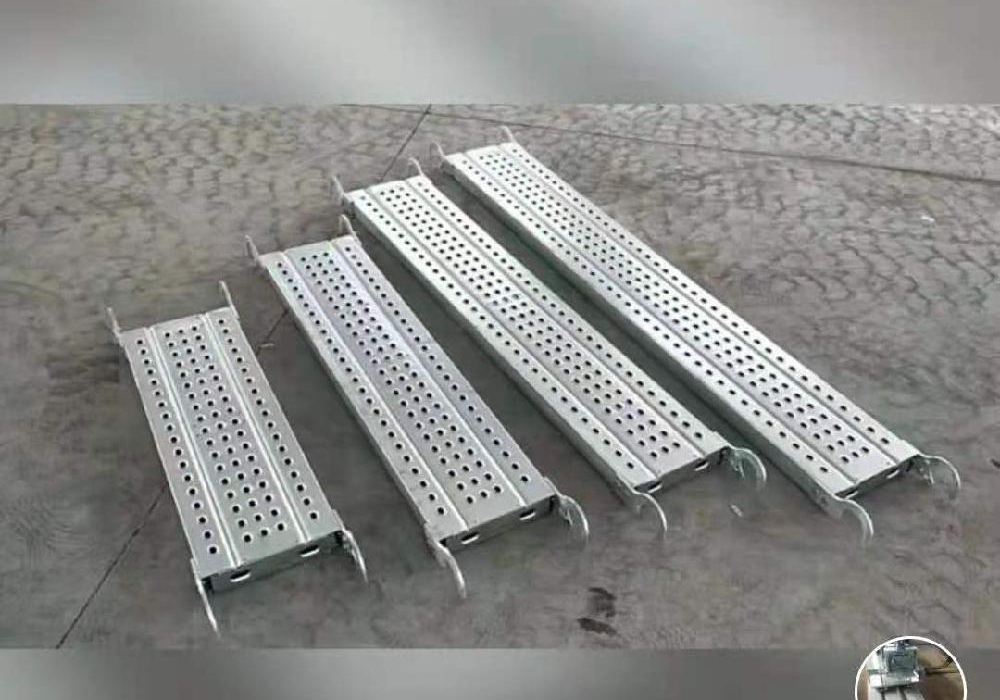

Scaffolding Roll Forming Machine

Scaffolding Roll Forming Machine

Most cable tray material is pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2.0mm.

Mean function of the cable tray and cap is support cable, protect cable and manage cable. If you want to learn more details of the cable tray machine, please contact us.

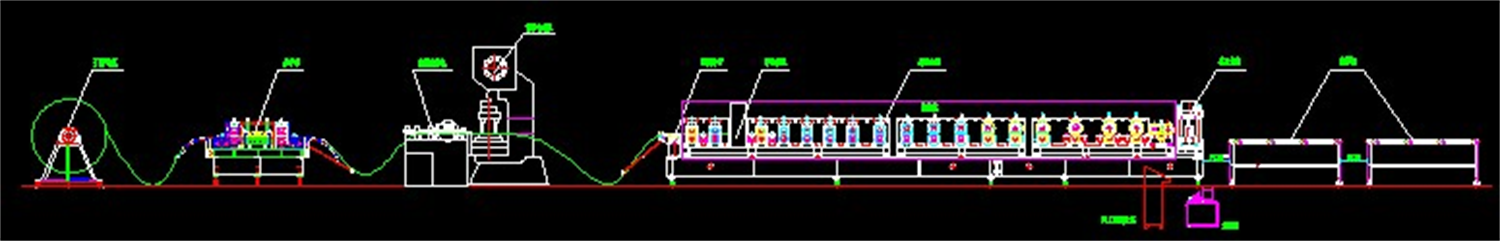

A. Technology Process

5T Hydraulic feeding→Guiding→servo feeding system→ punching→forming →leveling→cutting→output

B. Structure and features

This kind of guardrail roll forming machine which can make scaffolding plate

The machine is including 5T hydraulic decoiler, roll gang, leveling device, plate punching, cutting machine, hydraulic station, PLC system and output table, etc.

C.Main date

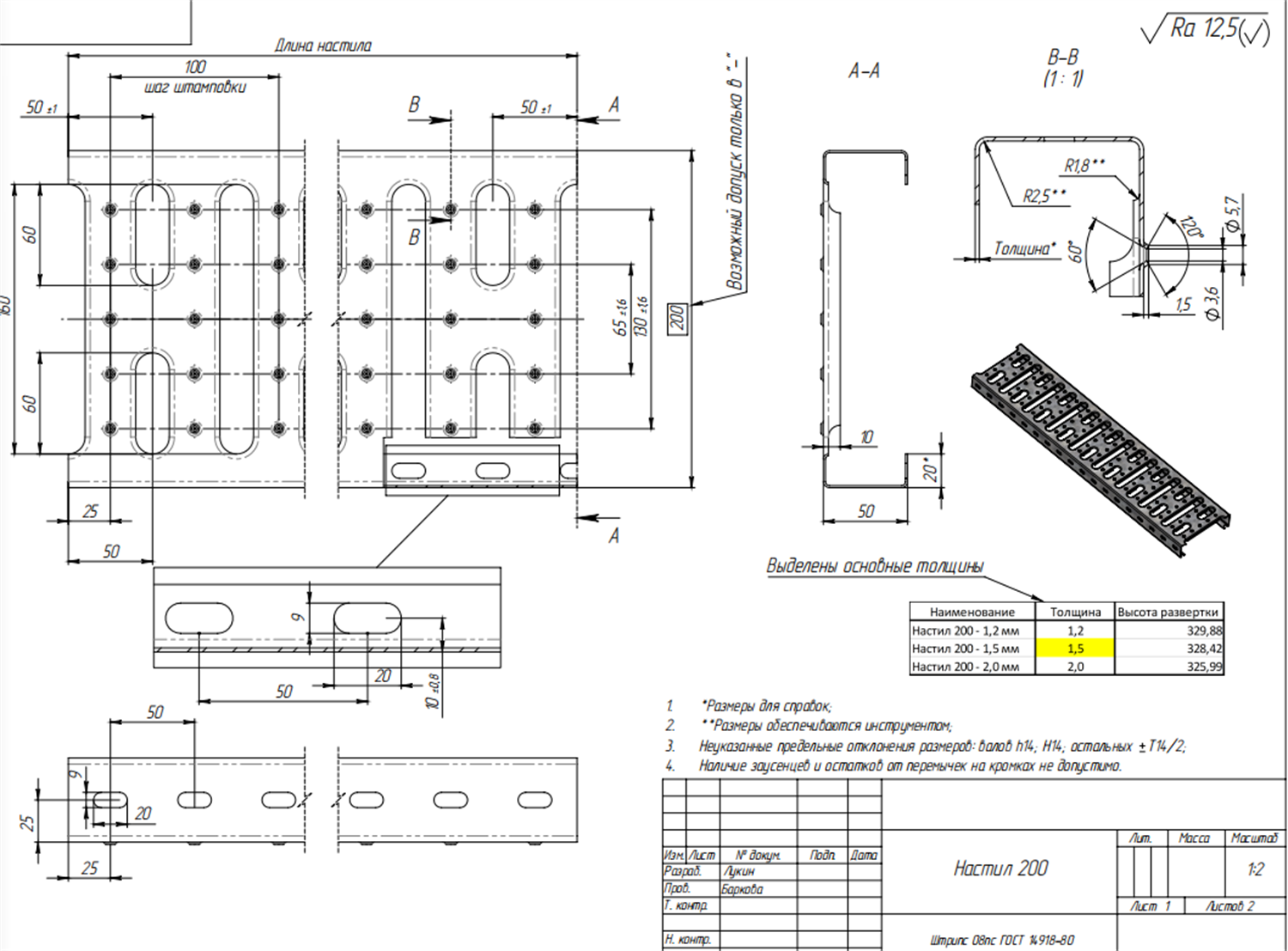

a)Raw material mechanical property and Spec.:

Material:Q235

Steel strip thickness: 1.5~1.8mm

Steel coil bore: φ508

Steel coil weight: ≤5T

b)Product Spec.:

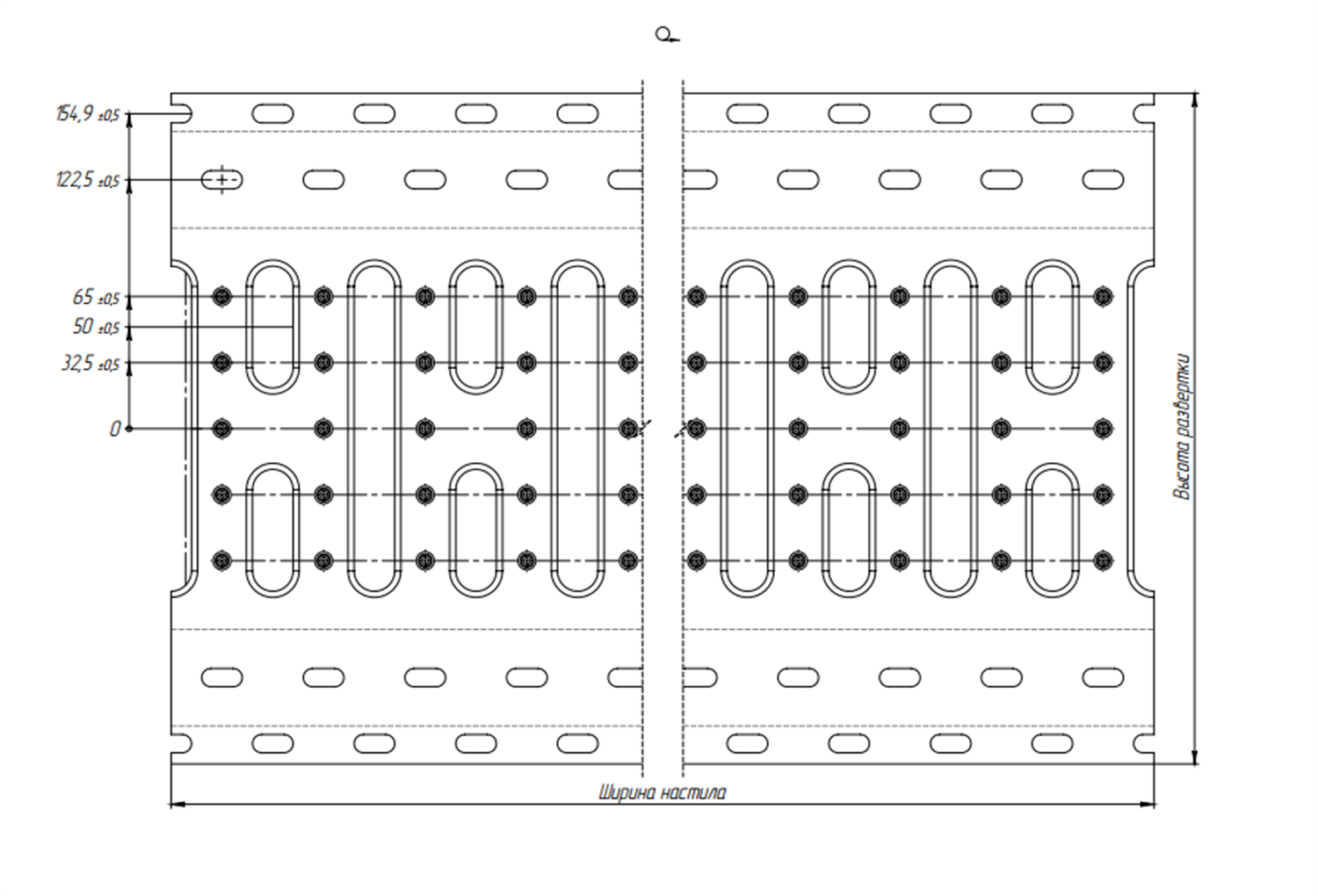

Product:According to the drawing

Width of the product: 320mm

Height of the product: 76.5mm

Length of the product: 1000-4000mm

Length tolerance: ±2mm

Precision of the work piece:Length±1.0mm,hole distance±1.0mm,straightness 0.5mm/M,width tolerance±3mm,punching location degree tolerance:≤0.5mm;degree of symmetry±1.5mm;

c)Technology Spec.:

Forming mode: cold roll forming

Working speed: 5-10 m/min

Feeding direction: Left feeding

Main voltage: According to the customer demands

Main motor power: About 37KW

D. Main parts data:

1. Decoiler:

Cantilever type manual decoiler, the load capacity is 5T, Coil boreφ500-600,Coil max diameterφ1200.

Motor power: 4KW

2. Leveling and feeding:

Wall board type leveling machine, two roller feeding, 9 roller leveling. Leveling material is 40Cr,quenching treatment hardness HRC58º~62º。The leveling machine has guiding

3.Servo feeding and punching machine

Function:feeding and punching

Structure:Servo feeding machine and gantry type three groups punching die. It can meet the drawing requirement. Servo motor and brand: YASKAWA motor 4.5KW.

Punching die material: Punch die use SKH51or DC53(equal to SKD11)die steel with forging and accurate grinding. HRC58-62.

4 Roll forming machine:

28 steps mail roller, individual open memorial archway type structure,the column structure material is HT200 with tempering.The stand column cross sectional dimension is 100×80, Shaft diameter is φ80 with thermal refining treatment.the roller material is GCr15, HRC58-62°. Single out shaft down drive gearbox has 28 pcs, bevel gear mod M=10,gearbox material is HT200。Main motor power 37 kw,common motor, using frequency converter to control the speed. We also match helical surface reduction gears, speed ratio 48.57. Using 1.5 inch double row chain to drive between the drive gearboxes.

5 Control system:

Using Siemens PLC control system, Yaskawa frequency conver, Siemens touch screen, it can control the all parts of the whole line.